Canadian Shield Consultants

Snyder Tanks

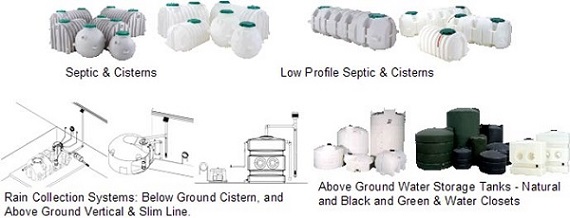

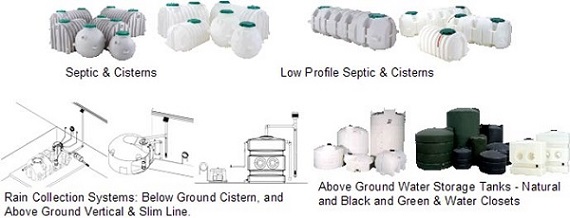

For many years, rotational molding has proven to be the ideal method of producing a seamless one-piece tank that minimizes the risk of leaking. In addition, polyethylene, because of its excellent corrosion resistance and chemical compatibility is the ideal material for on-site applications. And when properly molded, polyethylene can readily endure the stresses imposed by installation and burial loads.

At Snyder, we were not content to just develop a line of polyethylene tanks for the on-site/water markets. We developed designs to further enhance the leak proof properties of the tank(s) and improve the structure to minimize deformation of the tank(s) and maximize tank life.

The result is the best performing tanks available in the marketplace. That is why Snyder is the growing choice for on-site, water and rainwater harvesting applications.

For more than 50 years Snyder has been a leader in building plastic tanks that are lighter, stronger and more cost effective than other materials. In developing our water tank line, Snyder engineers studied the demands of each application and used computer enhanced design to strategically shape and strengthen tank walls to withstand stress.

Snyder can meet your water tank needs from five rotational molding plants. This enables faster delivery and keeps freight costs low. Most popular sizes are stocked at all locations.

From raw material analysis to stringent final inspection, the quality of Snyder’s Water Storage tanks is monitored every step of the way.