|

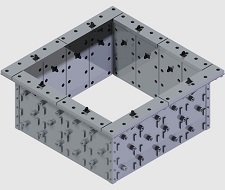

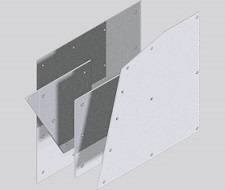

Carriere Industrial is a market leader in wear liner design, supply and wear management services for the mining, aggregate and process industries. Our experienced technical staff will assess your specific wear application and specify the ideal material, thickness, grade best suited for your operations. Carriere Industrial carries a full line of heat treated plate from 400 to 600 Brinell Hardness (BHN), carbide overlay plate, rubber, rubber ceramic, epoxy ceramic, silicon carbide, UHMW and many others to meet your operations specific wear problems. Carriere Industrial will also install engineered and approved lifting lugs to ensure ease of installation and all liners are individually identified with the part number, equipment and location to facilitate installation and improve maintenance turnaround time. Using our wear liner systems along with Linerwear, a fully interactive management software tool used to monitor wear parts performance, your mining operations will realize greater productivity along with lower costs and inventories and increased asset integrity. |