Home >

Suppliers Companies

> FLO Components >

Products > SKF Brand Lubrication Solutions > SKF LubriLean Minimal Quantity Lube System

FLO Components

SKF LubriLean Minimal Quantity Lube System

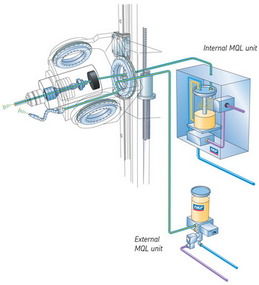

With an SKF LubriLean Minimal Quantity Lubrication (MQL) System, lubrication between the tool and work piece is performed by an aerosol - i.e. by oil droplets that are finely dispersed in an air stream.

With internal minimal quantity lubrication, an aerosol is produced in the equipment's reservoir and fed through the rotating spindle to the tool. When properly adjusted, the oil supplied is completely used up with no residue left behind.

With external MQL, lubricant and air are fed to the active area between the tool and work piece via tubing and nozzles. This relatively rigid system is suitable for machining operations in which the tools used are similar and the work piece contours do not change. It can also be used for series-produced parts.

Applications for SKF LubriLean include milling, rolling, shell end milling and form cutting, face milling, high speed cutting, hobbing, drilling, boring, tapping, buzz and band saws, forming and broaching. Some advantages include major reductions of up to 30% in overall production time, a more precise cutting process, better surface quality and significant increases in tool life.

Featured Products