Borets Canada

Progressive Cavity Pumps

In recent years the complicating factors, such as solids content, scaling, high GOR, high viscous fluids, low production rates, etc., have extended impact on the overall performance of the artificial lift equipment. The ESP application in such operating conditions is limited.

The most efficient artificial lift method that copes with these complicating factors is a progressive cavity pumping, since it brings a viable solution to the oil recovery issues for 70% of the difficult wells.

Borets offers the Submersible Progressive Cavity Pumps of the different design for the operation within the range from 350 to 3000 rmp, with the motors of different type and design:

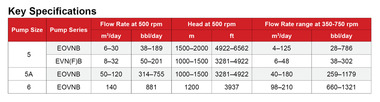

• Single Electric Submersible Progressive Cavity Pump – EOVNB series, 4 to 210 m3/day (28–1321 bbl/day), available in 5, 5А and 6 sizes.

• Twin-Opposed Electric Submersible Progressive Cavity Pump – EVNB series, 6 to 48 m3/day (38–302 bbl/day), available in size 5.

Operating components of the ESPCP are a stator and a steel rotor. The stator includes a steel housing, the inner surface of which is covered with oil-resistant elastomer or made of the composite material. The rotor is made of steel with wear-resistant coating.

The clearance between in the working pair and elastomer material are selected by the specialists of the Borets Company on the basis of the certain operating conditions.

F means that pumps are equipped with the motor seal 1PB92A, permanent magnet motor and clutch coupling placed between the motor seal and the motor.

The single progressive cavity pump consists of a right-hand threaded rotor and is placed in a right-hand threaded stator.

The twin-opposed pump has an upper left-hand threaded operating pair, while a lower operating pair is right-hand threaded.

ESPCP is available in several configurations

1. ESPCP system with Permanent Magnet Motor (PMM), operating at 350…750 rmp.

This system is equipped with a drain/check valve, motor seal, SPT series telemetry system, Borets-VDU VFD with backspin limiter, transformer and motor lead extension with a pothead.

2. ESPCP system with 4-pole Induction Motor (IM), operating at 1380 rpm.

The system is equipped with a drain/check valve, motor seal, SPT series telemetry system, Borets VFD, transformer and motor lead extension with a pothead.

3. ESPCP system with an induction or permanent magnet motor, operating at 1500…3000 rpm.

EOVNB-TSK series ESPCP is a new engineering design by the Borets Company.

The stator of the pump is made of the Oksafen composite material, armoured with the "stekloroving" what allows to pump high-viscosity oil and at high temperatures (up to 220ºС).

In comparison with the rubber-steel stator EOVNB-TSK series pump has a higher wear resistance, high resistance to the associated gas diffusion and to the influence of the chemically active substances.

The system is equipped with a drain/check valve, motor seal, SPT-2 series telemetry system, Borets VFD or Borets universal VFD, transformer and motor lead extension with a pothead.

EOVNB series ESPCP can be completed with the flush valves KPNB73.

Featured Products