Home >

Suppliers Companies

> Outotec (USA) Inc >

Products > Analyzers and Automation > Zinc Refining Control Solutions

Outotec (USA) Inc

Zinc Refining Control Solutions

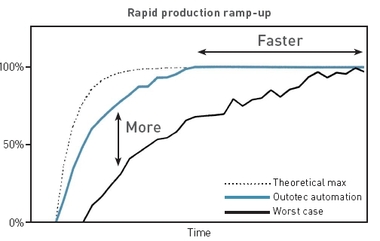

The ability to stabilize the process and to gain an overview of production is an important aspect of automation in zinc processes.

Balances between departments involved in operations, from roasting or direct leaching of different raw materials to casting, are difficult to see and control, Zinc refining process controlmainly due to long delays.

Benefits are gained in an easy and convenient manner while also improving operation, equipment, environment and personnel safety.

The Proscon® automation system is a process automation package, designed to transfer Outotec's process expertise to our clients. The complete application includes a process control system, process instrumentation and process electrification with all of the required services. Outotec deals only with modern, renowned and respected hardware and software manufacturers. Through our remote diagnostic online service, Outotec's metallurgical and automation expertise is available throughout all stages of the production life cycle.

OPTIMIZING ZINC LEACHING

Zinc leaching conditions are stabilized and optimized with a multivariable model-based control solution, which improves the overall performance of the zinc leaching line. The system keeps up with feed changes and eliminates disturbances that may arise in the process. The chemical equilibrium, composition of the leaching solution and recovery are determined and controlled continuously by adaptive models. Fuzzy models are utilized in order to conveniently incorporate the practical in-house operating knowledge into the control solution.

Featured Products