DSI Mining Canada

Tunneling

See Tunneling products

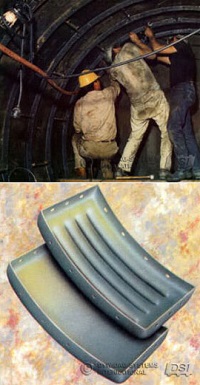

VIP-Heinke has unrivalled expertise in seal design and elastomer technology, and is one of the world’s leading manufacturers of elastomer gaskets for the segmental lining of tunnels, commonly known as tunnel segment gaskets (TSGs).

VIP-Heinke has unrivalled expertise in seal design and elastomer technology, and is one of the world’s leading manufacturers of elastomer gaskets for the segmental lining of tunnels, commonly known as tunnel segment gaskets (TSGs).

TSGs, which are located in precast grooves encircling the mating faces of each segment, give a secure rubber-to-rubber waterproof seal as soon as the segments are bolted together. The low compression set and stress relaxation values of the elastomeric compound used in their manufacture enable elastomeric TSGs to recover under reduced applied load thereby maintaining a positive seals between segments despite ground movements.

VIP-Heinke manufacture a range of TSGs designed for precast concrete, steel and cast iron segments used in the lining of tunnels or shafts and large mains sewers. All are precision engineered to meet the precise requirements of individual projects.

Elastomeric TSGs provide an economic and effective solution for sealing tunnels and shafts against water ingress. Compared to other sealing methods, elastomeric TSG's offer many benefits.

VIP-Heinke's Tunnel Segment Gaskets:

• are easy to install

• create an effective seal when bolts are tightened, immediately creating dry joints

• assure an effective seal despite ground movement and alternating wet and dry conditions

• have a proven reliability, eliminating the need for costly remedial work to seal leaks after construction

• have a proven track record of durability, being resistant to chemical attack and microbiological degradation

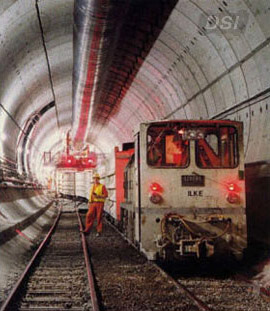

DSI's selection of underground supports, the widest in the world, affords the contractor, the designer, and the owner a matchless combination of high performance and tunneling at low cost.

DSI's selection of underground supports, the widest in the world, affords the contractor, the designer, and the owner a matchless combination of high performance and tunneling at low cost.One of these products alone - liner plates - offers these outstanding advantages:

• Economy of construction in time, excavation, material, manpower.

• Maximum support per given length with minimum weight of steel.

• Standard variation of plate design for all shapes of tunnels in dry or wet ground.

• Predictable strength, fire resistant.

• Continuous support during the critical mining phase in soft ground tunneling.

• Easy to store, handle and erect, whether the tunnel is straight, curved, circular, elliptical or horseshoe in shape.

• Gasket plates that seal joints, stop water leakage and reduce air loss when water is a problem.

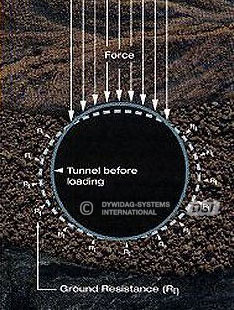

Steel liner plates provide a relatively light-weight, easy-to-handle, safe support for soft ground tunneling because the ground that supplies the loading also supplies the resistance to the load. The liner plate assembly simply distributes and transmits the load to the surrounding earth. As a steel liner plate ring takes load vertically, it tends to deflect inward at the top and outward at the sides. The ground resists deflection of the lining by developing a passive force equal in magnitude and opposite in direction to the force exerted by that of the lining. The diagram on the left illustrates this principle.

The ability of the surrounding ground to resist the outward bulge of the liner plate ring is the key to vertical load support. With the ring confined to a small amount of deflection, the thrust line induced by the load is forced to follow the ring of liner plates. Thus, the ability of the assembly to withstand the applied load depends upon its ability to transmit ring thrust from plate to plate around the ring. Obviously, this ability is enhanced by the four-flange design of DSI's plates.

The ability of the surrounding ground to resist the outward bulge of the liner plate ring is the key to vertical load support. With the ring confined to a small amount of deflection, the thrust line induced by the load is forced to follow the ring of liner plates. Thus, the ability of the assembly to withstand the applied load depends upon its ability to transmit ring thrust from plate to plate around the ring. Obviously, this ability is enhanced by the four-flange design of DSI's plates.

Liner Plates

There are various methods for determining the required strength of tunnel linings. Nevertheless, the type of ground, the location and depth of cover, the size and length of the tunnel, level of ground water, superimposed loading, and history always guide these calculations.

DSI liner plates can be purchased in 16" and 24" widths as corrugated or smooth plates. Liner plates are formed from one piece of metal to provide longitudinal and circumferential flanges. The plates can be galvanized and/or bituminously coated and grout holes with plugs can be included. For special conditions gasketed liner plates and tapered liner plates can also be manufactured. Liner plates can be installed alone or in conjunction with steel ribs if additional support is required.

System Description

System Description

DSI was a pioneer in the development of rock and soil anchor systems and technology for the Tunneling and Mining Industry. Today DSI is a world leader in this field with an outstanding reputation of product quality and customer service. The double corrosion protected THREADBAR® anchor is universally recognized as the "standard" for anchor performance and corrosion protection. DSI is dedicated to the advancement of the "State-of the Art" for rock anchors ready to support you during the design, planning and construction of your project. When questions arise, contact your nearest DSI representative.

DSI offers a complete line of THREADBAR® designed for both temporary or permanent use, manufactured from materials best suited to meet the needs of your project.

| DYWIDAG Rock Anchors are generally used to: | THREADBAR® Anchors |

|

• Anchor external forces and uplift forces

• Anchor retaining walls

• Stabilize eccentrically loaded foundations, slopes, • rock walls and cuts

• Stabilize underground excavations and mines

• Increase the stability of dams

|

are available in 1" (26 mm), 1-1/4" (32 mm) and 1-3/8" (36 mm) nominal diameter, in lengths up to 60 feet (18.3 m) without couplers, with a guaranteed minimum ultimate tensile stress of 150 or 160 ksi (1034 or 1103 MPa). |

Special steels for high impact, seismic and low temperature applications can be made available on special order.

Prestressed rock and soil anchors have become an important tool for the Tunneling engineer. Their safe and reliable use in both permanent and temporary applications is accepted throughout the world.

Rock Anchors are post-tensioned bars installed in drilled holes for which at least the entire bond length is located in rock. The anchor force is transmitted to the rock by bond between the grout body and the rock. Rock anchors can remain unbonded in the free stressing length allowing the anchor to be checked and retensioned at any time. In such cases, adequate corrosion protection for the stressing anchorage and the free stressing length must be provided. On the other hand, the free stressing length can also be fully grouted after the anchor has been stressed, in which case force adjustment is no longer possible.

| As a full service organization, DSI is prepared to supply design assistance and practical field know-how. This service can also be used to optimize the design process by helping to select the anchor system best suited to meet specific project requirements. The regional warehouse and fabricating centers strategically located throughout North America, coupled with an extensive network of local sales/service centers, provide prompt, reliable response to customers needs. Most orders can be supplied from inventory with short lead time. To minimize site labor and to optimize quality control, a variety of shop prefabricating services are available for both bar and strand anchors. |

In many cases the anchors can be delivered to the site ready for immediate installation without the need for site assembly. The application of corrosion protection grouting at the job site can also be minimized and in many cases completely eliminated, saving time and money. In some locations both supply and installation, including drilling services, are available for any size project.

Whatever you need you can count on DSI for quality from start to finish. The dedication of our staff to quality and service will help you complete your project successfully and on time.

|

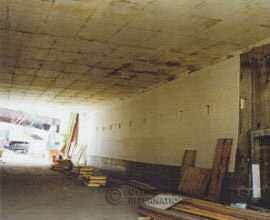

PROMAT Fire Protection Boards sandwich panels have been utilized in countless new and retrofit tunnel and underground construction projects worldwide.

PROMAT Fire Protection Boards sandwich panels have been utilized in countless new and retrofit tunnel and underground construction projects worldwide.

Ease of installation and replacement, cost effectiveness, and superior performance have made this product line the premier choice of owners and designers for structural protection, fire-life safety requirements, and architectural finish needs.

PROMAT applications include the protection of the concrete tunnel linings with the boards utilized as part of the formwork or attached to existing concrete. Wall and ceiling applications have been successfully tested to all the important international hydrocarbon standards, including the most stringent RABT and RWS fire curves. Other assemblies meeting the standard ISO classifications ( E119, DIN, BS476,etc.) include ventilation ducts, cable trays, partition walls, and structural steel.

PROMAT autoclaved calcium silicate boards- being resistant to moisture, the effects of freeze-thaw and de-icing salts, and possessing excellent structural properties, easily handles the harsh environment and the design concerns of the underground construction sector.