American Mine Door

When using flexible trailing cable in a mine, damage is a fact of life.

When using flexible trailing cable in a mine, damage is a fact of life.

Reducing downtime is a high priority. American Mine Door's cable vulcanizer offers sturdy construction that stands up to heavy use.

Our light weight aluminum frame model allows for easier transporting from point to point in and out of the mine.

Our steel frame cable vulcanizer is favored inside many cable repair shops. With our steel frame unit weighing in at 152 lbs and our sturdy aluminum frame cable vulcanizer coming in at a mere 75 lbs, portability can be taken for granted.

The innovative and proven design of American Mine Door's cable vulcanizer has been used in the mining industry for years, making jobs easier and safer.

• Steel Frame Cable Vulcanizer (less handle) 152 lbs.

• Aluminum Frame Cable Vulcanizer (less handle) 73 lbs.

Features of AMD Cable Vulcanizers

• Accepts most mine cable molds

• Accepts most mine cable molds

• Fast clamping action

• Easy to load and unload

• Sturdy construction will withstand the mining environment

• Open front - no tie bars

• Snap action thermostats

• Indicating lights

Components of Cable Vulcanizer

|

Voltage

Watts

Platens

Bench Space

Set Temperature

Temperature Adjustable

Acme Screw

Net Weight

Throat Opening Standard

Throat Opening High Back

|

Most

3000

6-1/2 x 20

16 x 20

300 degrees

240 / 350 degrees

1-1/2 - 4 thread

150lbs.

6 inches

10 inches

|

Want to know more?

Contact Us today, or:

American Mine Door's Model 75 is a rugged, heavy-duty Track Cleaner ready to remove iron, copper, coal, potash, and salt from your tracked mine.

American Mine Door's Model 75 is a rugged, heavy-duty Track Cleaner ready to remove iron, copper, coal, potash, and salt from your tracked mine.

Designed to serve in a variety of underground mining environments, our Model 75 Track Cleaner operates while hitched to a locomotive. It cleans your mine track using two methods:

• Using the Forward Plows, the track cleaner scoops excess debris from the outside of the railway. Once set to the best position, the plows funnel the debris into the center area between the tracks.

• Between the rails is a Digger Plate traveling 1" above the railroad ties when in digger position. The digger plate strips through any debris which has compacted along the tracks. Loosened material is funneled up the digger plate onto a gathering conveyor chain. The gathering chain conveys debris onto a boom conveyor and then in to a receiving rail car being pulled by the Track Cleaner (coupled together).

Contact Us today, or:

Specifications on the AMD Model 75 Track Cleaner

Our Model 75 Track Cleaners (formerly the Canton Track Cleaner) have a clean spillage rate exceeding 1 TON per minute, clearing the roadbed for a distance of 6' 6" from the centerline on each side of the track and leveling the roadbed a total of 13' 0" out to out with plow extensions. A medium size locomotive tows the cleaner, one or more empties, and the change motor.

Our Model 75 Track Cleaners (formerly the Canton Track Cleaner) have a clean spillage rate exceeding 1 TON per minute, clearing the roadbed for a distance of 6' 6" from the centerline on each side of the track and leveling the roadbed a total of 13' 0" out to out with plow extensions. A medium size locomotive tows the cleaner, one or more empties, and the change motor.

• Standard Frame Height 46"

• Optional REMOTE CONTROL operation

• Caging Length 13'

• Caging Width 6' 6"

• Track Gauges 30" to 48"

• Horsepower and Starter Horsepower 50

• Maximum Cleaning Width, Standard 10' 0"

• Maximum Cleaning Width with Plow Extensions 13' 0"

• Conveyor Drives Hydraulic

• Approximate Weight 18,000 lbs.

• Rail Weights All

• Voltages DC, AC, Battery, Diesel

• Motor-Full Duty Load 1 hour

• Pump-Hydraulic-3 stage-GPM 50

• Speed - Boom Conveyor 183 FPM

• Speed - Gathering Conveyor 211 FPM

• Minimum Height 38"

• Overall Length 32'

• Motor RMP 17,500

• Reducers - Two Planetary reducers for independent drives

• Side Plates 1"

• Digger Plate - Abrasion Resistant 1"

• Boom Skip Sheet - Abrasion Resistant 1/4 :

• Boom Chain - Ave. Ultimate Strength 91,000 lbs.

• Conveyor Chain - Ave. Ultimate Strength 90,000 lbs.

• Dual Control Standard

• Conveyors-Forward/Reverse Independent Drive

• Independently driven, reversible conveyors permit quick clearing of stalled conveyors.

Optional Features for Model 75 Track Cleaner

• Removable Plow Extensions

• Jointed Boom / Front End (Cage Loading)

• Provisions for Dual Track Gauge and Rail Weight

• Staple Lock Type Fitting in Lieu of JIC

• Water and Ditch Control Assembly Gathering Conveyor Dual Operation Digger Plate Area Underside of Boom

|

|

|

| High Pressure Mine Door | Low Pressure Mine Door | Personnel Man Door |

American Mine Door Co. has two main door designs available for the Mining Industry, a high-pressure door that has been used around the world for over 50 years and a new low pressure door. Our “low pressure” doors are a lighter design and economically priced for less demanding applications . We also offer our popular Personnel Man Doors.

Operation of the AMD Mine Ventilation Door

Our door wings open in opposite directions. This unique design feature allows our mine doors to withstand many inches of water gauge pressure. The same air pressure that assists the door in opening also assists it in closing. Consequently, air pressure is equalized.

Ramp slope effects are cancelled as one door wing operating downhill aids the other wing uphill. Due to the equal force principal, our mine doors can be installed in almost any slope application.

To assure maximum lifetime value, our mine doors are reusable, and can be easily moved from one location to another.

Mine Door Options and Features

Custom Controls for Mine Door Operation (PLC)

Custom Controls for Mine Door Operation (PLC)

American Mine Door Co. has the ability to design and build control systems to work with your door package. We can custom design a system that operates lighting systems and audible alarms, create door interlocks (one door cannot open if another door is open), thru door scanners (door will not close on objects), remote control operation, sonic trip sensors etc.. We discuss your unique control needs and assist you in designing the safest and most productive systems for your situation.

Want to know more?

Contact Us today, or:

Features of the Mine Ventilation Door

Each door is custom designed to the customer's specific needs.

Door size ranges from 5'-0" - 23'-0" Wide to 5'-0" - 16'-0" High.

Custom PLC (programmable logic control) solutions for specific customer requirements.

Electro-hydraulic, pneumatic and manual actuation systems available.

We can manufacture doors that withstand up to 800,000 inches per pound torque of air pressure.

Working together, multiple fans and the door operation itself contribute to the ventilation control of the mine.

American Mine Door's ventilation doors remain closed if air currents are reversed.

Allows traffic into neutral airways, where a permanent stopping is impossible to construct.

Ventilation mine doors can be moved and installed in new locations, if necessary, avoiding expensive overcasts.

Reduces icing conditions by installing an American Mine Door at the portal.

Used in all types of underground mines: coal, uranium, salt, gypsum, clay, gold, potash, sodium, titanium, molybdenum.

Additional Features

Steel Frames and Steel Panels

Our mine doors come equipped with steel frames and steel panels, double-acting cushioned air cylinder, 17 gallon air storage tank, and control cabinet. Your choice of manual or optional photo-electric operation. Optional signal lights show position of door at all times. Air compressor with air storage tank available for those mines that do not have ready access to compressed air.

Air Cylinder

Double-acting cushioned cylinder is equipped with control valves for adjusting the opening and closing speed of the door wings. Optional rope pull contactor, slap type contactor or photo-electric operation located in-by, and out-by each door provide for a positive opening and positive closing each time. Eliminates waiting time by mine personnel and maintains constant speed through haulage ways.

Control Cabinet

Manual override on valve allows for operation of door several times in event of power failure. A shut-off cock, check valve (to maintain pressure in the air reservoir receiver should line pressure fall), filter, lubricator and solenoid valve are all mounted in a heavy sheet metal enclosure.

Door Automation

The American Mine Door Co. has the ability to design controls to operate your mine door package. After initial review of your specific needs, we will offer the customer a written description of exactly how the control system we design will operate. At that time, the customer will review the system operation overview and make any final alterations that they want included. American Mine Door Co. will build the controls in-house, complete a thorough testing of the system, and then complete wiring schematics and installation instructions for the customer.

Automation control highlights:

Automation control highlights:

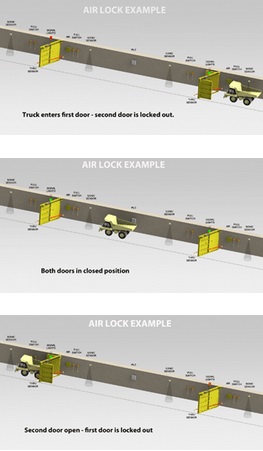

• Increase safety and productivity while maintaining air lock integrity by using an American Mine Door Co. PLC automation package.

• 1 door, 2 door “air lock” and 3 door “T” automation control packages available. Each automation package is unique and has been proven in hundreds of installations in many types of mines.

• Our control packages have evolved over the last 10 years by listening to our customers’ needs.

• We only use the highest quality enclosures and components to assemble packages to survive many years of trouble free service.

• We will custom design and program automation packages to solve any unique customer issue.

Our controls packages offer the ability to automate your air locks. Secure your air lock by locking out one door, use thru-door scanners to detect obstacles between the doors to avoid injury or damage. Open/close doors via sonic sensors to detect vehicles approaching and exiting your doors - eliminating idle time”

Control Features:

• NEMA 12/13 enclosure

• Allen Bradley Micrologix 1000 PLC

• Line conditioner in each system

• All Allen Bradley components (relays, terminal blocks, switches, fuse holders etc.)

Available options and programmable logic control packages:

• Door interlock logic – lock out 1 door in airlock to maintain neutral airways.

• Logic for “T’s” and “cross” traffic patterns.

• Lighting systems (green, red and yellow shows traffic conditions).

• Buzzer/ horns for audible alerts.

• Rope pull switches – used to manually open/close a mine door.

• Thru-door scanners – scan between the door wings during the close cycle to detect anything between the doors. If any object is identified during the close cycle the doors wings will immediately open to avoid injury or damage.

• Sonic sensors – located on the roof of the mine, a sonic sensor is placed a predetermined distance at the entry and exit of the mine door. When the sonic sensor identifies a moving object, a signal is sent to the PLC which signals the door to open or close. These can be used in track or trackless mines very effectively, significantly reducing idle time at each mine door.

• Remote control systems via remote transmitters.

• Cap lamp sensors to activate door systems.

• Above ground controls of your mine doors via Ethernet communication cable.

• Bump style safety curtains affixed at the door wing edge (at center where door wings come together). Used as an E-stop in the event an object comes into contact with the curtain.