FLO Components

Off-Road Lube Systems

AUTOGREASERS INCREASE RETURNS ON YOUR EQUIPMENT INVESTMENT

Bearing failure resulting from improper lubrication is a major cause of equipment downtime and significant unnecessary maintenance costs in today's environment. The majority of failures are caused by: contamination of bushings by dust, dirt and moisture; inadequate amounts of lubricant applied to bearings; or over-lubrication of key pivot points.

Direct costs resulting from inadequate lubrication can include: replacement bearings; labor to repair or replace bearings; lost time and its impact on productivity. Indirect, but very real costs include: wasted lube, environmental issues, safety or housekeeping issues, and higher labour costs related to inefficient manual lubrication practices.

FLO AUTOMATIC LUBRICATION SYSTEMS

Designed for extreme weather conditions and severe job requirements often faced in Canada, the completely reliable and fully automatic FLO Lubrication System will increase your component life and overall productivity. The system dispenses small measured amounts of grease at frequent intervals while your equipment is operating, maintaining a consistent lubricant seal to prevent dirt and contaminants from migrating into your bearings. It will help keep your equipment out on the job and reduce your labor costs when compared to the traditional method of point-by-point manual lubrication.

Increases life of critical wear points = Protect your investment

Less unplanned downtime = Increase your profits

Reduces operator involvement = Keep your operators focused on their primary job.

Improves safety = You don't have to climb over and under equipment to lubricate.

Fewer replacement parts to stock = Lower your operating costs

Increases resale value of your equipment

Uses your standard NLGI #2 in-shop grease = No inventory of higher-cost grease.

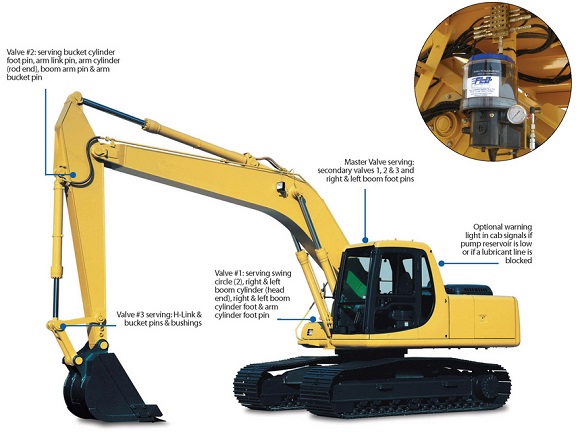

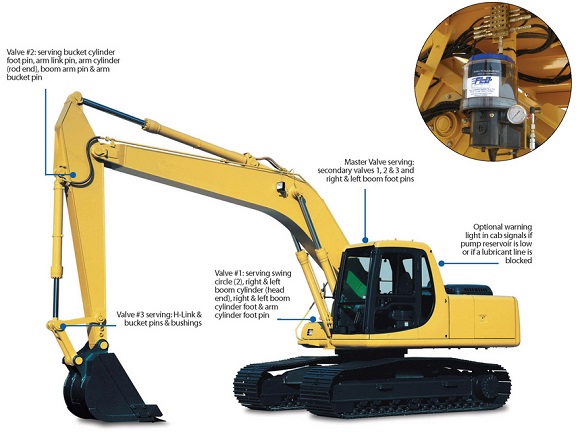

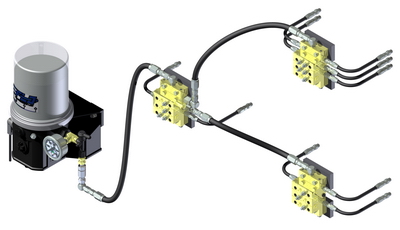

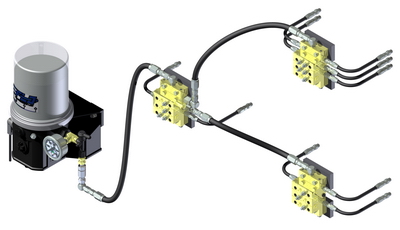

TYPICAL CENTRAL LUBRICATION SYSTEM LAYOUT

FLO's installed Automated Lubrication System consists of a 12/24 VDC Series 203 pump, UV positive displacement grease metering valves, fittings, tubing, hose and custom guarding. Pumps include an integrated adjustable timer for easy installation, trouble-free operation and maximum flexibility. Reservoirs range from 5 - 15 lbs. Our automated greasing systems service steering cylinders, center articulation, oscillating axles, lift cylinders, boom anchors, bucket joints, transmission hanger bearings, suspension cylinder, dump box pivots, drill mast bearings, hammer surfaces, "H" links on excavators, and more. The FLO lubrication system is suitable for most off-the-shelf North American greases currently in your shop. It will handle lubricants up to an NLGI #2 rating to -25 °C or -13°F.

Protects your Critical Breakers / Hammers. The pump attaches directly to your hammer, gripper or crusher and is connected to the hydraulic power supplier of the carrier.

Using your Wire Rope Lube System, the old lubricant and grit are mechanically scraped from the grooves and surfaces of the wire ropes.