Tech Directional Services

Past Projects

Shell Canada, Muskeg River Mine

This project took place during the first six months of 2013. As usual we offered directional support for this horizontal drilling using the DeviDrill™ system and magnetic surveys using the DeviShot™ multi shot tool. For the first time we offered horizontal Gyro services using the SPT Gyro Tracer Directional™. With the help of our Technical staff and the support of Shell Canada this project was an overall success.

Aurico Gold – Young Davidson Project – Ontario

From April 2012 to November 2012, TECH Directional Services worked on the Aurico Gold Young Davidson Project. To achieve our targets we were steering near or beyond 1000 meters. The North seeking Gyro was used to keep track of the location and trajectory of all drill holes.

Goldcorp Cochenour Project – Red Lake – Ontario

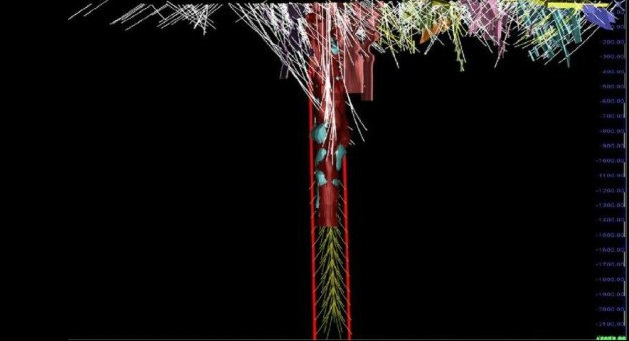

This surface drilling program started in January 2011 and was completed in November 2012. This project consisted of four drills which were monitored and directional corrections made as needed. Most of the Directional work was done between 1000 to 1500 meters in depth. For many of the first holes that were collared we needed to steer around old mine workings to enable us to hit the targets required. This was done successfully time after time. To ensure survey accuracy while drilling these holes we used our North seeking Gyroscope.

Vale Nl – Voisey’s Bay Project – Labrador

Since October 2010 TECH provided Directional Drilling Services and Gyro Surveying as required on a surface infill drilling program. Although drilling in hard formations our technicians were able to successfully steer the holes and overcome the difficult terrain.

Rainy River Resources Gold Project – Northwestern Ontario

In October of 2011 we began providing directional drilling and downhole survey support to this high profile 12 drill rig program in Northwestern Ontario. Because of the strong natural deviations it was necessary to use directional drilling to consistently hit deep targets.

S&ME Engineering – Louisville Geotechnical Tunnel Project – Louisville, Kentucky

In 2011, Tech Directional Services, working through S&ME provided directional control on three, 2300 foot (700 meter) horizontal geo-technical holes. These holes were in support of pre-construction investigative work on the Ohio River Bridges, Kentucky East End Approach Tunnels being carried out by the Kentucky Department of Transportation. Offset limits requested by S&ME required maintaining a +/- 20 foot (6 meter) offset to the end of hole to stay within the Pillar and Tunnels construction limits.

Team Drilling – Cameco McArthur Mine Project – Saskatchewan

TECH Directional provided technical support on the McArthur Mine drilling program in 2011 to Team Drilling. Working together we consistently hit targets within 5 meters during this time period.

Hudbay Lalor Project – Snow Lake, Manitoba

TECH Directional was working at the Lalor Project fulltime from Jan 2007 to Dec 2011. At times we have provided 2 directional teams; one working the delineation drilling program and the other providing support for regional projects. We have a high success rate accurately hitting 10 meter diameter targets at depths between 700 to 1400 meters. We have successfully steered two 1000 meter vertical pilot holes keeping them within a 6 meter diameter cylinder to depth.

Aurora Energy Resources – Michelin Project – Labrador

One of three fly jobs that TECH Directional has been involved in, Directional work was required because the target locations were located under a lake. Using the Directional drilling method they were able to hit multiple targets from one set up without having to move the drills location. This was the most environmentally friendly approach.

Claude Resources – Madsen Mine Project – Red Lake, Ontario

This project was an interesting one for several reasons. It was an underground drilling program that was taking place while the mine was being dewatered. Because of the water the mining company was unable to set the drills up in the lower levels of the mine. The ore body we were drilling was below all the mines workings making it impossible to drill a straight line to target. It was necessary for us to drill around multiple drifts and other mine workings to get on line to target. Through extensive Surveying and Directional work, we successfully drilled around all the workings in the mine without breaking out into the workings.

Creso Resources Inc – Minto Pit Project – Sudbury, Ontario

Cypress Development Corporation – Red Lake, Ontario

FNX Mining – Sudbury, Ontario

Gestion IAMGOLD – Rouyn-Noranda, Quebec

Goldcorp Red Lake Mine – Red Lake, Ontario

For two years TECH Directional worked on an extensive Directional Drilling program underground at Red Lake Mine in Balmertown.

Hy-Tech Drilling – Cameco McArthur River Project – Saskatchewan

Kirkland Lake Gold – Kirkland Lake, Ontario

In 2009 we were contracted to steer three paste fill holes from surface that would break out into the mine at depths ranging from 1100 to 1400 meters. The goal of this project was to drill an oversized HQ hole for paste fill. In order to steer this diameter of hole we needed to reduce to NQ then using the Devico system steer the hole. Once the Directional work was completed we then would ream the cut with the oversized HQ rods. This procedure was repeated as required. Gyro surveying was used as support for this project. All three holes were completed by February 2010 breaking out within ten feet of the intended breakout points.

Noront Resources – Ring of Fire Project – James Bay Lowlands, Ontario

TECH Directional provided directional drilling services and Gyro surveying for one year beginning in the second half of 2009 to the high profile Ring of Fire Project at the James Bay Lowlands.

North American Palladium – Lac des IIles Mine – Thunder Bay, Ontario

Delineation Drilling began from surface while a suitable location was prepared underground to complete the work. We offered two different types of surveying while on site. Using the Deviflex system we would survey the horizontal underground work and using the SPT North Seeking Gyro we would survey surface directional work.

PC Gold – Pickle Crow Mine – Pickle Lake, Ontario

This job began late 2009 and finished in the spring of 2010. We worked mainly on two drill setups steering holes where the client felt they had the best chance of a successful intercept.

Rambler Metals & Mining – Ming’s Bight Mine – Newfoundland

TECH Directional provided Directional Drilling Services for two deep mother holes. Multiple branches off each hole were completed passing through the target zones within a 10 meter radius at depths of over 1400 meters. When required, TECH provided surveying support using the Maxibore II system.

Rubicon Minerals – Phoenix Gold Project – Red Lake, Ontario

Thundermin Resources – Little Deer Project – Newfoundland

Vale Inco – Sudbury, Ontario

This work took place at multiple locations around the Sudbury Basin. When holes would start to go offline we would be brought in to correct the dip and azimuth making it possible to accurately hit deep targets.

Guyana Goldfields – Aurora Deep Directional Project – Guyana

The Aurora exploration camp in Guyana started in 2011 and was completed in spring 2012. It was one of the most challenging projects we have faced to date. The unique cylindrical shape and rock composition of the gold deposit tested the limits of the DeviDrill system both in rock hardness and in target depths ranging from 1450m to 2000m.

Wallbridge Mining – Sudbury, Ontario

Xstrata Nickel – Fraser Mine – Fraser Tailings Project – East Range Project – Sudbury, Ontario

Xstrata Zinc Canada – Matagami Project – Matagami, Quebec

Source: http://www.techdirectional.com/past-projects/

Careers With Us

Requirements: High School Diploma, basic knowledge of computers and programs, a mechanical inclination, valid Driver’s license, valid Standard First Aid Certificate, positive work Attitude.