Burkina Faso is a landlocked nation. It is surrounded by six countries: Mali to the north, Niger to the east, Benin to the south east, Togo and Ghana to the south, and Côte d'Ivoire to the south west. It covers and area of 274,000 km² and has an estimated population of more than 13,200,000. The Essakane deposit is located within a 100.2 km² mining permit that is surrounded by six exploration permits covering a total area of 1,266km².

History

The Essakane deposit has been an active artisanal mining site since 1985. Between 1989 and 1991, the Bureau des Mines et de la Géologie du Burkina (BUMIGEB) undertook regional mapping and geochemical programs and arranged and financed a program of heap leach test work. The Compagnie d’Exploitation des Mines d’Or du Burkina (CEMOB) acquired a mining permit over the site in 1991, and from 1992 to 1999 carried out heap leach processing of gravity rejects from the artisanal winnowing and washings.

BHP Minerals explored the area from 1993 to 1996 under a joint venture agreement with CEMOB. Coronation International Mining Corporatioin ("CIMC") secured title in 1996 following the liquidation of CEMOB, and in July 2000 acquired six new exploration permits. In September 2000, CIMC optioned the project to Ranger Minerals ("Ranger") who completed several phases of drilling over artisanal mining sites including Essakane, Falagountou and Gossey. Following Ranger's withdrawal from the joint venture, CIMC was approached by Orezone Resources with an offer to merge the companies. The merger was papered in March 2002 and Orezone Resources became 90% owner of the project.

Gold Fields entered into a joint venture agreement with Orezone Resources in July 2002. Orezone Resources was the initial operator of the project until Gold Fields assumed management responsibilities in January 2006. Gold Fields completed a Pre-feasibility Study in the third quarter of that year and finally earned a 60% interest in the project upon completion of a Feasibility Study in September 2007. In October 2007, Orezone Resources entered into an agreement with Gold Fields to acquire its 60% interest and reclaim its 90% ownership of the project.

IAMGOLD commenced management of the Essakane project following the acquisition of Orezone Resources in February 2009.

Milestones

1985 Discovery of Essakane by artisanal miners

1992 BUMIGEB constructs heap leach plant

1993 CEMOB / BHP Minerals exploration joint venture

1996 CIMC secures title following liquidation of CEMOB

2000 Exploration by Ranger Minerals

2002 Orezone / Gold Fields joint venture

2006 Gold Fields completes Pre-feasibility Study

2007 Gold Fields completes Feasibility Study

2007 Orezone Resources acquires Gold Fields interest in the project

2009 IAMGOLD acquires Orezone Resources 2010 Commercial production July 16, 2010

Geology

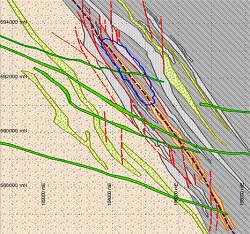

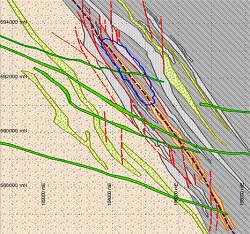

The Essakane Project occurs in the Paleoproterozoic Gorouol greenstone belt in northern Burkina Faso. The local stratigraphy can be subdivided into a succession of lower-greenschist facies metasediments (argillites, arenites and volcaniclastics), conglomerates and subordinate felsic volcanics, and an overlying Tarkwaian-like succession comprising siliciclastic metasediments and conglomerate. Each succession contains intercalated mafic intrusive units that collectively comprise up to forty percent of the total stratigraphic section.

The region preserves evidence for at least two regional deformational events. D1 structural elements such as the Essakane host anticline are refolded by a series of NNE-trending F2 folds. Later localized deformation occurs near the margin of a calc-alkaline batholith in the south of the project area. The Markoye Fault trends NNE through the western portion of the project area and separates the Paleoproterozoic rocks from an older granite-gneiss terrane to the west.

Mineralization

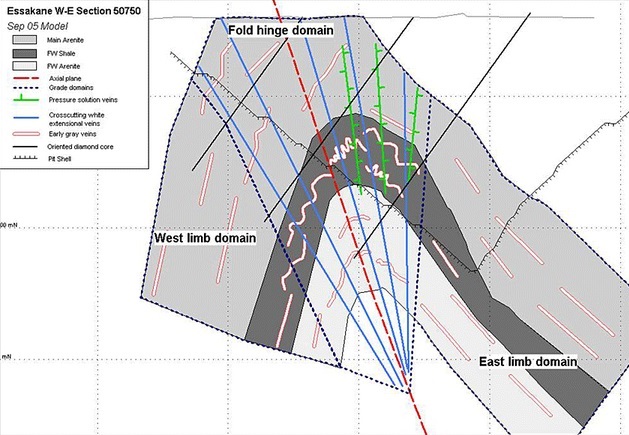

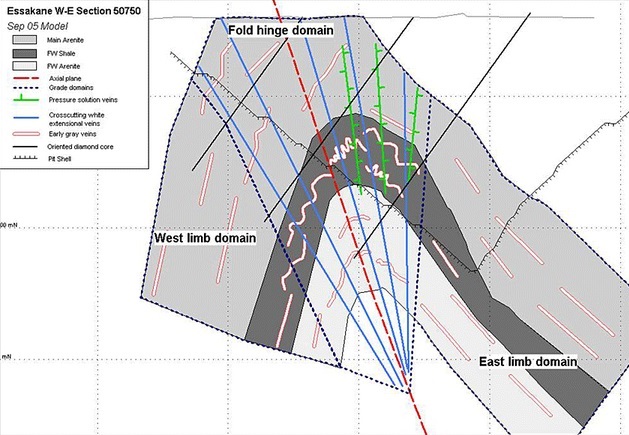

Essakane is an orogenic gold deposit characterized by quartz-carbonate stockwork vein arrays and is hosted within the lower meta-sedimentary sequence. The deposit occurs in an upright asymmetric anticline that plunges shallowly to the northwest. The highest concentration of quartz veins and gold mineralization occurs in the 50-70m thick ‘main arenite unit’, and spatially in the hinge zone and eastern fold limb of the host anticline.

There are two distinct structural controls on gold mineralization: (i) gold associated with bedding parallel deformation; and (ii) gold associated with structures formed by the anticlinal folding event. The vein arrays are complex and consist of: (i) early bedding parallel laminated quartz veins; (ii) late steeply dipping extensional quartz veins; (iii) axial planar veins and pressure solution seams in the fold axial zone.

Alteration in the host arenite unit typically consists of a sericite > carbonate > silica ± albite ± arsenopyrite ± pyrite assemblage. Arsenopyrite and pyrite occurs within and adjacent to quartz veins are disseminated throughout areas of wallrock alteration. Traces of chalcopyrite, pyrrhotite, galena and hematite can occur with the arsenopyrite. Gold occurs as free particles within the veins and also as intergrowths in arsenopyrite on vein margins or in the host rocks. The regolith profile within the deposit area consists of one to three metres of laterite, a 30 to 50 metre thick upper saprolite zone and a 10 to 30 metre thick lower saprolite zone that is underlain by competent rock. The Essakane deposit has a strike length of 2,500 metres and is open to the north, although economic mineralization follows the fold plunge to become progressively deeper. Mineralization has been confirmed to 270 m vertically below surface but the full depth extent in the fold hinge and east limb has not been tested.

Mining

Feed to the plant is a blend of three designated ore types commencing predominantly with saprolite and transition material (saprock) for the first three years. Fresh rock mill feed will gradually increase from Year 4 onward. Milling rates will be 7.5 million tonnes per year for the first three years of operation, 6.5 million tonnes per year for the fourth year and 5.4 million tonnes per year thereafter when mill feed is entirely fresh rock.

Mining is carried out using a conventional drill, blast, load and haul surface mining method with an owner fleet. Annual mining rates are estimated at 32 million tonnes per year for the first four years, decreasing to 25 million tonnes per year until eventually stabilizing at 15 million tonnes per year. Grade control samples are collected using reverse circulation drills with blast hole rigs used for production drilling. Loading is accomplished using hydraulic excavators and wheel loaders.

Processing

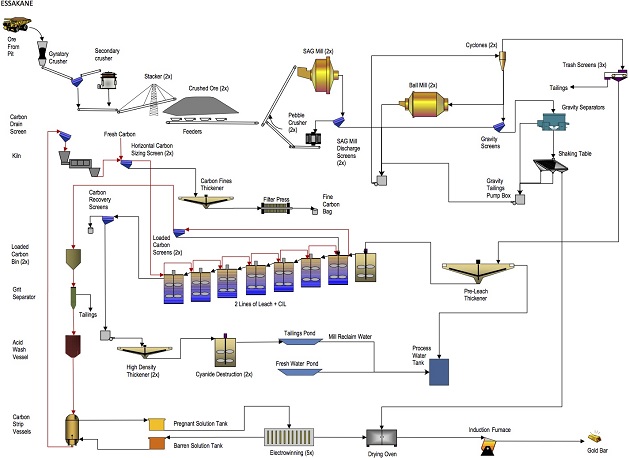

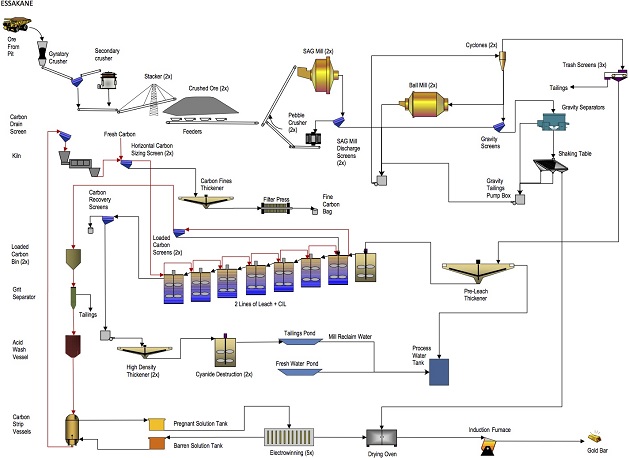

Essakane ore is processed using conventional crushing, milling and carbon-in=leach ("CIL") gold plant.

The mine plan calls for predominantly saprolite and transition ore feed in the initial four years of operation, followed primarily by fresh rock ore feed for the remaining mine life. Essakane realized an opportunity to increase mill throughput during the initial four years of operations and thereby increase forecast gold production, reduce unit operating costs and improve financial returns despite a marginal increase in capital costs.

Furthermore, by taking advantage of grinding in cyanide, optimizing slurry density by thickening ahead of leaching and the inherent faster leaching kinetics of saprolite, it was concluded that no additional CIL tankage was required and no significant impact on recovery would be observed at a plant throughput of 7.5 M tpy for predominantly saprolite and transition ore feed.

The Essakane project is located in north-eastern Burkina Faso, West Africa. It straddles the boundary of the Oudalan and Seno provinces in the Sahel region of Burkina Faso and is approximately 330 km northeast of the capital, Ouagadougou. It is situated 42 km east of the nearest large town and the provincial capital of Oudalan, Gorom-Gorom.

The Essakane project is located in north-eastern Burkina Faso, West Africa. It straddles the boundary of the Oudalan and Seno provinces in the Sahel region of Burkina Faso and is approximately 330 km northeast of the capital, Ouagadougou. It is situated 42 km east of the nearest large town and the provincial capital of Oudalan, Gorom-Gorom.

Essakane is an orogenic gold deposit characterized by quartz-carbonate stockwork vein arrays and is hosted within the lower meta-sedimentary sequence. The deposit occurs in an upright asymmetric anticline that plunges shallowly to the northwest. The highest concentration of quartz veins and gold mineralization occurs in the 50-70m thick ‘main arenite unit’, and spatially in the hinge zone and eastern fold limb of the host anticline.

Essakane is an orogenic gold deposit characterized by quartz-carbonate stockwork vein arrays and is hosted within the lower meta-sedimentary sequence. The deposit occurs in an upright asymmetric anticline that plunges shallowly to the northwest. The highest concentration of quartz veins and gold mineralization occurs in the 50-70m thick ‘main arenite unit’, and spatially in the hinge zone and eastern fold limb of the host anticline.