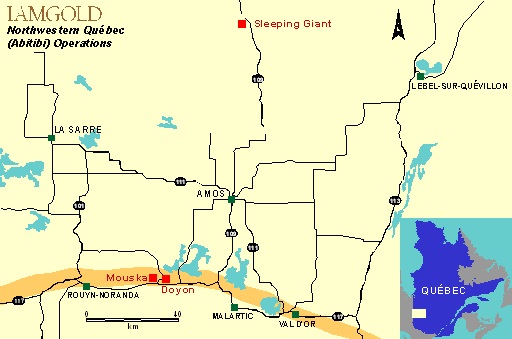

The Doyon Division is comprised of the Doyon and Mouska underground gold mines, located approximately 40 kilometres east of Rouyn-Noranda and 80 kilometres west of the city of Val d’Or in northwestern Québec, Canada. The Doyon Division covers an area of 2,258 hectares and is situated within the Cadillac-Bousquet gold belt in the Abitibi region, one of the most prolific gold mining camps in Canada. The Doyon property consists of 116 claims and a mining lease that covers 1,381 hectares. The Mouska property is contiguous with the western border of the Doyon property. This 877 hectare property is held through 22 claims and two mining leases.

The mines of the Doyon Division are readily accessible year round by existing paved roads and benefit from available water supply and electric power supply sources.

The 120 kilometre stretch separating the cities of Rouyn-Noranda and Val-d’Or is scattered with producing and past producing mining projects including: Mouska, Doyon, Bousquet, LaRonde and Lapa.

In 2004, surface drilling discovered the Westwood deposit two kilometres east of the Doyon mine. Continued positive results led to a decision to undertake a significant underground resource delineation exploration program.

History

The Cadillac-Bousquet region in northwestern Québec has been a productive mining centre for over 100 years and still holds great potential. In 1972, it became the co-property of Silverstack Mines Company Ltd. and the Québec government controlled Soquem Inc., which carried out exploration between 1972 and 1975. In 1975 Long Lac Mineral Exploration Ltd (Lac Minerals Ltd), took over Silverstack’s interest. Commercial open pit mining began at the Doyon Mine in 1980, and while underground mining commenced in 1985, the full transition to a wholly underground operation was completed in early 1989. The Doyon Gold Mine has been a significant producer of gold for the past 30 years having produced over 5 million ounces of gold.

In 1986, Cambior Inc. acquired an initial 50% interest in the Doyon Gold Mine and 100% of the Mouska property in connection with the privatisation of most of Soquem’s assets. Cambior became the sole owner of the Doyon Gold Mine by acquiring the remaining 50% interest from Barrick Gold in 1998.

Underground exploration at Mouska began in October 1987, pre-production development followed in May 1990 and commercial production commenced in July 1991. IAMGOLD acquired the Doyon Division including both the Doyon Gold Mine and Mouska Gold Mine through its merger with Cambior in November 2006.

The Doyon mine ended operations in December 2009. In the fourth quarter of 2009, the Company approved a program to extend the life of the Mouska Mine to early 2012, through the use of paste backfill produced from the Doyon paste plant.

Milestones

1975 Doyon Gold Mine acquired by Soquem Inc. and Lac Minerals

1980 Commercial open pit mining commences

1985 Commercial underground mining commences

1986 Cambior acquires 50% interest in Doyon Gold Mine and 100% of Mouska Gold Mine

1991 Mouska Gold Mine commences production

1994 Barrick Gold acquires Lac Minerals 50% interest in Doyon Gold Mine

1998 Cambior acquires remaining 50% interest in Doyon Gold Mine from Barrick Gold

2005 Resumption of mining at Mouska Gold Mine following deepening of internal shaft

2006 IAMGOLD acquires Doyon and Mouska Gold Mines through Cambior transaction

2008 IAMGOLD purchases the participation royalty from Barrick Gold

2009 The Doyon mine closed in December. Mouska's mine life was extended to 2012.

Geology

The Doyon Division lies in the southern portion of the Archean Abitibi volcanic belt within the Bousquet Formation of the Blake River Group (“BRG”), otherwise known as the Cadillac-Bousquet gold belt in the Abitibi region of Québec. The stratigraphy trends east-west and dips steeply to the south. The BRG is overlain to the north by sedimentary rocks of the Kewagama Group and overlies sedimentary rocks of the Cadillac Group to the south. The contacts between the BRG and the adjacent sedimentary groups are characterised by extensive zones of deformation.

The Cadillac-Bousquet belt is one of the largest gold producing districts of the Abitibi greenstone belt, Québec’s most productive metal mining region. The belt hosts several large deposits including La Ronde, Bousquet 2, Bousquet 1, Doyon and Mouska. These deposits lie within the intensely altered and deformed corridor of the BRG known as the Doyon-Dumagami deformation zone. Current reserves and resources combined with historical production from these mines exceed 21 million ounces of gold.

Mineralization

The Doyon gold deposit is dominated by vein-type mineralization, with the main mineralized veins averaging several centimetres in thickness. Vein assemblages typically comprise varying proportions of pyrite, quartz, chalcopyrite, carbonate and gold.

The deposit can be divided into three parts: Zone 1, Zone 2 and West Zone. Zones 1 and 2 occur exclusively within volcanic rocks whereas West Zone mineralization is hosted by the Mooshla intrusive.

The Mouska Gold Mine lies in the southern part of the Abitibi subprovince, in the Bousquet Township. It is hosted by volcanic and plutonic rocks of the BRG. Volcanic rocks dominate and areprimarily basaltic to andesitic in composition. The Mouska deposit is classified as an orogenic lode-type deposit. Economic mineralization is associated with laterally and vertically continuous narrow quartz veins of less than one metre in thickness. Veins strike ESE, dip subvertically and contain 5-15% pyrite-pyrrhotite and 5-10% chalcopyrite.

Economic lenses occur in andesitic volcanics and in the Mooshla intrusive, which occupies the southeastern third of the property. The intrusive hosts the current known reserves and has the best potential for resource expansion.

Mining

The mining method used at the Doyon Gold Mine is sub-level stoping with paste backfill. At the Mouska Gold Mine, shrinkage stoping and long hole stoping are used. All ore extracted from the Doyon Division is processed onsite.

The Doyon mine has both a shaft and a ramp for mobile equipment access. Once the ore has been mucked from the drawpoints, it is transported to the nearest ore pass and goes to one of the two crushers. Once crushed, the ore is loaded into skips from one of two automatic loading stations and hoisted to surface by the production hoist. At surface, the ore is transferred to the ore bin and then onto the mill for processing.

Processing

The 3,500 tonnes per day Doyon processing plant uses the carbon-in-leach (CIL) and carbon-in-pulp (CIP) processes to recover gold and produce gold bullion from Mouska ores and flotation. These produce a gold bearing copper concentrate that is then shipped to a smelter for final metal recovery. Copper is a by-product and is credited against Mouska’s production costs.

The Doyon Gold Mine facilities and equipment include a conventional mill equipped with a SAG mill and cyanidation and CIP processing facilities, a flotation circuit, a high-density sludge plant, a water treatment plant, a tailings pond and settling pond, electrical and mechanical maintenance shops and a headframe, mechanised mobile underground equipment, as well as a warehouse, a paste backfill plant and an administrative building.

Mouska Gold Mine’s principal facilities include a headframe, a service building housing electrical and mechanical shops and an administrative office. Access to underground is via a main shaft of 485 metres and an internal shaft of 560 metres. The internal shaft is located 1.2 kilometres east of the main shaft.