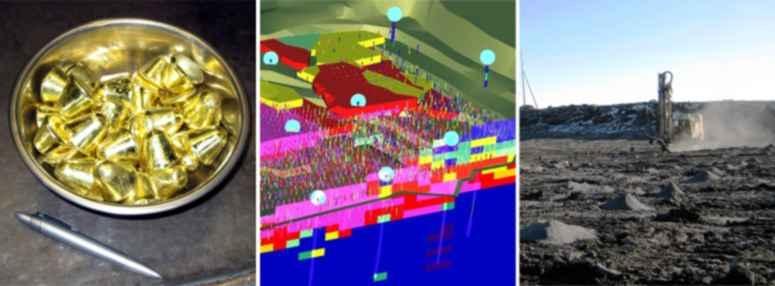

Grade Control and Reconciliation

Understanding grade distribution and optimising mining selectivity through grade control is essential to achieving the mine plan. SRK has the expertise to implement, monitor, analyse and react to grade control data. This expertise allows the results to be reconciled against planned production and actual plant data. Minimising the difference between planned verses actual production will improve business performance.

Approach

When analysing grade control methodology, SRK considers: detailed geological controls on grade distribution, optimal sample spacing, sample collection, sample preparation and analysis, quality control, and optimising costs and benefits.

When undertaking reconciliation studies, SRK considers: resource models used for short and long-term mine planning, mining selectivity, dilution, losses and ore allocation records, stockpile records, plant feed records and production results.

Experience

SRK employs a number of geologists with significant operational experience. In their previous roles as mine geologists at various international operations, their duties included grade control, optimising the selective extraction of ore and routine reporting of the multiple components of reconciliation.

Our geologists possess a sound understanding of the full spectrum of mining operations, coupled with geological modelling, sample theory and their practical application.

SRK has a large skill base in the use of advanced mining software packages, such as Datamine, GEMS, Vulcan and Surpac, Leapfrog and Minex, and has a good understanding of the estimation methods suited to grade control in many different styles of deposit and different commodities.

Services

• On-site design, implementation and review of systems, protocols and processes

• Differentiation of ore types for mining and processing

• Reconciliation studies between resource models, grade control models and plant feed records

• Optimisation of stockpiling and blending strategy

• Identification of problems and troubleshooting

• On-site training related to data capture, analysis and reporting for regular production reviews

|