Detour lake is the second largest gold producing mine in Canada with the largest gold reserves and substantial growth potential.

The Detour Lake open pit mine is located in northeastern Ontario, approximately 300 kilometres northeast of Timmins and 185 kilometres by road northeast of Cochrane, within the northernmost Abitibi Greenstone Belt.

The mine is situated in the area of the historic Detour Lake open pit/underground mine operated by Placer Dome which produced 1.8 million ounces of gold from 1983 to 1999. The Detour Lake operation has a mine life of approximately 22 years with an average gold production of 659,000 ounces per year.

Quick Facts

|

Location |

Approximately 300 kilometres northeast of Timmins and 185 kilometres by road northeast of Cochrane |

|

Mine Type |

Open Pit |

|

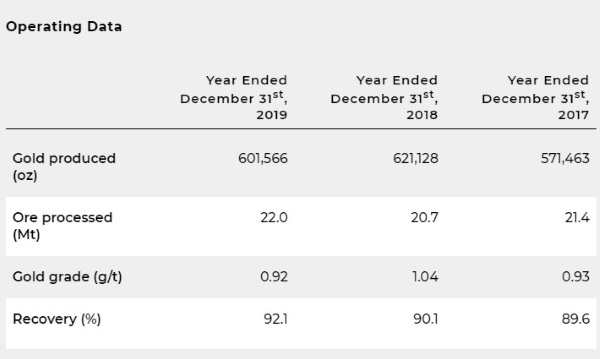

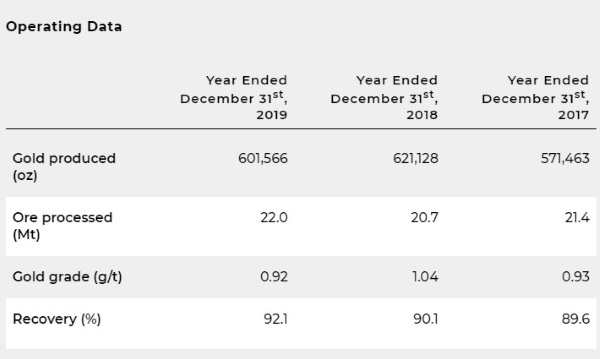

2019 Production |

601,566 ounces |

|

Deposit Type |

Orogenic lode gold

Vein/narrow vein

Hydrothermal

|

|

Process |

Gravity separation

Concentrate Leach

Agitated Tank Leaching

Carbon-in-pulp (CIP)

Solvent Extraction and Electrowinning

Cyanide (reagent)

|

|

End Product |

Gold doré |

|

Infrastructure |

55 ktpd or 61 ktpd |

|

Commenced Operation |

2020 by Kirkland Lake Gold, producing since 2012 by Detour Gold and 1983-1999 by Placer Dome |

Exploration

Zone 58N

Gold mineralization was identified in the Lower Detour area on a splay off the Lower Detour Deformation Zone (LDDZ) in three spatially related mineralized horizons – 58, 58N and 75 Zones. It remains open for expansion at depth and up and down plunge. These mineralized lenses share characteristics with the Sigma-Lamaque deposits of the southern Abitibi (Robert 1986). Gold mineralization within Zone 58N is hosted by a swarm of feldspar porphyry dykes from near surface to a vertical depth of approximately 800 metres and along strike up to 500 metres. Mineralization is associated with laminated quartz +/- tourmaline +/- carbonate veins and stockworks commonly with visible gold. Strong sericite, silica, chlorite and biotite alteration is associated with the mineralization event and envelopes veins. Sulphide abundance is variable, ranging from 0.5 to 5%, and typically occurs as disseminated pyrite with much lesser amounts of sphalerite, chalcopyrite, and Bi-tellurides. Above the 58N Zone is the 75 Zone which is hosted at the contact of high-Mg and high-Fe rich mafic tholeiitic units. Mineralization is associated to a highly silicified mylonitic unit with strong biotite-sericite alteration and locally up to 20% sulphides mainly as pyrite. Higher gold content correlates to higher sulphide abundance and proximity to Zone 58N.

Metallurgical testing performed on a total of 31 composites has confirmed that Zone 58N mineralization is amendable for processing through the existing Detour Lake processing plant. All composites were tested for grinding, gravity separation and cyanide leaching of both gravity products (concentrate and tails). Based on these initial tests, gold recovery is estimated at 97.5% for the stated mineral resource grade.

Mining method and processing

Conventional open pit mining methods are used to mine the Detour Lake deposit utilizing a current fleet size of 34 haul trucks (CAT 795F - 300 tonnes), 2 electric cable shovels (48 m3), 5 hydraulic shovels (28 m3), 12 drills and various ancillary equipment to support the mining operation. The mining fleet will be increased in the next few years to meet the mine production schedule of the new life of mine plan.

The crushing circuit includes a larger gyratory crusher (60"X113" HD equipped with 1,000 kW) and the addition of a secondary crushing circuit (2X750 kW crushers). In addition, this system is complemented with additional crushing capacity in the pebble crushing circuit (2X750 kW pebble crusher).

The milling operation is using a conventional gravity, cyanidation and carbon-in-pulp processing facility currently operating at approximately 60,000 tpd.

The grinding circuit consists of two parallel lines, each having one twin pinion semi-autogenous (SAG) mill (36'X20') and one twin pinion ball mill (26'X40.5'). The gravity circuit currently recovers approximately 25% of the gold. The remaining gold in ore is sent to cyanidation followed by carbon in pulp (CIP) gold recovery. After carbon stripping, the gold is processed through electrowinning cells prior to gold pouring. The overall gold recovery is estimated to average between 91-92% for the life of the mine.

The cyanide solution is recycled to the head of the circuit to reduce operating costs and environmental impact. The remaining stream is detoxified through an SO2/air system before tailings deposition. The Company is using the same location for the tailings impoundment facility as the former operation. The current tailing facility will be expanded to a second and then a third containment system with capacity for approximately 650 million tonnes.

Burntbush Property, Ontario

The Burntbush East and West properties are strategically located along the Casa Berardi deformation zone in the Abitibi Greenstone Belt, approximately 35 and 75 kilometres respectively, west of the Casa Berardi gold mine operated by Hecla Mining Company, which has produced approximately 1.9 million ounces of gold since it commenced production in 1988.

In general, exploration on the Ontario side of the Casa Berardi fault has been minimal due to limited access, overburden and the lack of outcrop exposures. Historical and more recent exploration activities have focused on the main structural break. The Burntbush grassroot properties cover more than 80 kilometres of primary (EW) and secondary (NE-SW) subsidiary faults. It also encompasses a number of gold anomalies intersected in old diamond drill holes, including an intercept of 6.41 g/t over 2.9 metres drilled by Newmont in 1985, and in till samples from a 2005 regional program by the Ontario Geological Survey. Immediately east of the West claim group, drilling by Lakeshore Gold in the mid-2000s delineated a 500 metres gold mineralized horizon (Porphyry Creek Zone). Within the East claim group, in the portion not controlled by Detour Gold, a small NI 43-101 compliant gold resource (A8 3200 Vein System) was reported in 2013 by Alpha Minerals.

Geology & mineralization

Gold mineralization at the Detour Lake Property is characteristic of greenstone-hosted orogenic lode gold style deposits. Gold reserves are contained in the (Detour Lake and West Detour deposits) spatially associated with the Sunday Lake Deformation Zone (SLDZ) which extends for over 30 kilometres on the Property. Further south the property hosts the Lower Detour Deformation Zone (LDDZ) which extends over a distance of 30 kilometers on the Property and is spatially associated with the 58N Zone.

The Detour Lake Mine and West Detour zones are hosted in an east-west mineralized corridor traced along a strike length of over 8 kilometres and a width of several 100s of metres. All gold mineralization at the Detour Lake and West Detour deposit is found north of the SLDZ.

The gold mineralization occurs in several different rock units within broad sub-vertical mineralized envelopes and splits into several sub-vertical domains sub-parallel to the orientation of the SLDZ. The Main Zone is the largest gold-bearing mineralized zone and consists of gold mineralization occurring in a fine grained silicified and sulphidised horizon or in quartz and quartz carbonate vein systems splaying off the SLDZ.

West of section 19,620E, the mineralization mainly straddles the lower massive flow-pillow flow contact and is commonly associated with increased biotite alteration, shearing, narrow quartz veining and minor pyrite or pyrrhotite. Local zones of strong brecciation with sulphide infilling have also been recognized along with minor chalcopyrite, telluride minerals and visible gold. Visible gold is usually found as clusters or fracture coatings. The gold mineralization is associated with a series of sub vertical to arcuate deformation zones characterized by enhanced strained fabrics, well defined open-space breccias, and to a lesser degree sheeted shear hosted extensional quartz veins.

The footwall mineralization (Talc Zone) is hosted in highly altered (i.e. serpentinized and talcose) ultramafic flows with mineralization concentrated at both the upper contact and lower contact of the SLDZ. It commonly contains boudins of quartz veins and felsic as well as intermediate dyke slivers. It is generally intensely sheared, especially in the area adjacent to the contact with the volcanoclastic sediments. Gold in the Talc zone is dominantly associated with pyrite-pyrrhotite and minor chalcopyrite along foliation planes, narrow discrete shears or strain zones, and in irregular lenses (Barclay, 1993). The zones also contain short deformed lenses or boudinaged quartz veins.

In the West Detour area gold is closely associated with a moderately to strongly sheared Mg-rich ultramafic komatiitic volcanic unit. Shearing and gold mineralization in this area is generally referred to as the M Zone which extends several 10’s of metres north and south of this unit and has been traced by drilling for approximately 5 kilometres. The gold mineralization styles are near identical as to the Detour Lake mine. Gold mineralization is within a relatively weak quartz vein stockwork with a low sulphide content (mainly pyrite and pyrrhotite). Approximately 200 metres north of the M Zone, the North Walter Lake Zone (“NWLZ”) is in a zone of high strain with deformed quartz veins within pillowed to massive mafic volcanic flows. Mineralization is associated with moderate to strong shearing, potassic alteration of the mafic volcanics, narrow quartz veining and minor pyrite and pyrrhotite.