The Macassa mine is a high-grade gold producer, with grade improving at depth, and a key valuation driver for the company.

The Macassa Mine, located in the Town of Kirkland Lake, Ontario remains one of the highest gold grade mines in the world. Macassa commenced operations in 2002, and with the discovery of the South Mine Complex (SMC), has been able to increase its level of production significantly over the past five years. The SMC has been driving grade improvement at Macassa, with results from ongoing exploration drilling continuing to extend the SMC mineralization and adding to the Mine's Mineral Resources in support of growing production and extending mine life.

The mine is located in an area with well-developed infrastructure, including a provincial highway, a railway system and a private airport. High-grade ore is processed at the Macassa Mill, which currently has available capacity and is located in close proximity to the mine.

Quick Facts

|

Location |

Town of Kirkland Lake, 580 km north of Toronto, Ontario |

|

Mine Type |

Underground, shaft access |

|

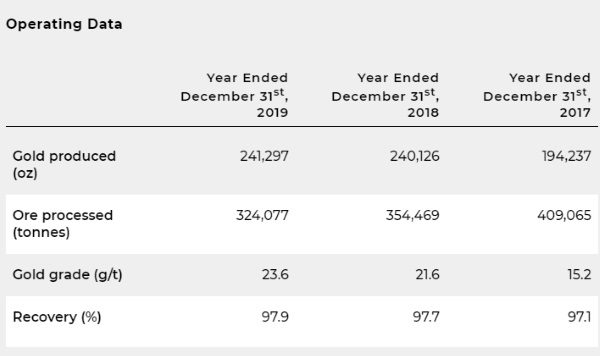

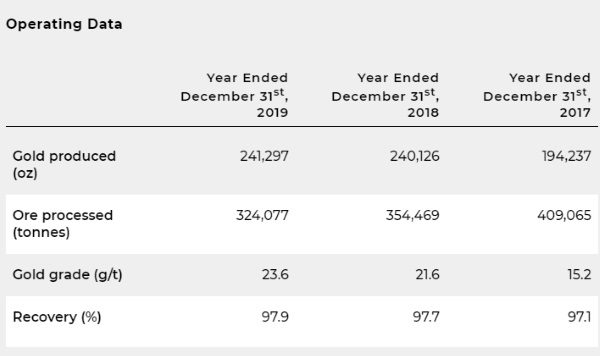

2019 |

Production 241,297 ounces |

|

Deposit Type |

Orogenic greenstone hosted gold (Lode Gold deposit) |

|

Process |

Carbon in Pulp (CIP) |

|

End Product |

Gold doré |

|

Infrastructure |

#3 Shaft, 2,200 tpd capacity Macassa Mill (ore and waste) |

|

Commenced Operation |

2002 by Kirkland Lake Gold, producing since 1933 |

Exploration

In 2012, Kirkland Lake Gold acquired the Hurd McCauley claim, along with the South, East and North claims, facilitating expansion drilling of the SMC in multiple directions.

Current underground exploration programs at Macassa are focused on underground drilling and drifting (on the 5300 Level) and include the delineation and extension of the SMC to the east, west and to depth, testing of the Amalgamated Break from the 5300, 5600 and 5700 levels and testing of the Main Break near the former Kirkland Minerals property between the 600 and 6500 levels, proximal to the location of the new #4 shaft. As of the end of September 2019, a total of 67,646 metres of underground drilling had been completed at Macassa during 2019.

#4 Shaft Project

On January 17, 2018, the Company announced plans to sink a new shaft at Macassa. The new, 21.5-foot diameter, concrete-lined shaft will offer a number of important benefits to the mine, including: de-risking the operation; enabling more effective underground exploration to the east of the South Mine Complex; improving ventilation and general working conditions in the mine; and supporting higher levels of production and lower unit costs. The new four-compartment shaft will have a total hoisting capacity of 4,000 tonnes per day (ore and waste) and is an important component of the Company’s plan to increase production at Macassa with a goal of reaching over 400,000 ounces per year over the next five to seven years.

Construction of the shaft will be completed in two phases. The first phase will be to a depth of 5,450 feet and include a mid-shaft loading pocket. Completion of phase one is targeted for the second quarter of 2022 at a capital cost estimated at $240 million (approximately $40 million of expenditures planned in 2018). Phase two of the project will be undertaken following the commencement of production from phase one, and will involve extending the shaft to an ultimate depth of approximately 7,000 feet. Completion of phase two is targeted for the end of 2023 at an estimated capital cost of approximately $80 million. The Company has not completed a National Instrument 43-101 level feasibility study on the shaft project.

A significant milestone was achieved in the second quarter of 2019 with the commencement of full-face sinking following completion of surface infrastructure construction. As of the end of September 2019, shaft sinking had advanced over 400 feet. The project remains on schedule for phase 1 completion in the second quarter of 2022.

Mining method and processing

Mining at Macassa is currently underway at an average rate of 1,000 tpd across two mining horizons: the historical Main/’04 breaks (15% of 2017 throughput) and the new SMC Zone (85% of 2017 throughput) with access via #3 shaft. In the Main/’04 breaks, mining is taking place between the 3400 and the 5300 levels. In the SMC Zone, mining occurs between the 5000 and the 5800 levels; the Company has completed the development of a haulage ramp down to the 5800-level elevation and will complete the ramp down to the 6000-level elevation by the end of 2018.

Mining is conducted primarily via overhand and underhand cut-and-fill and a small portion of long hole methods. All stopes are backfilled with either paste fill, cemented rock fill or loose waste rock. The Macassa Mine was the first mine in the world to use lithium ion battery operated trucks and loaders, which has allowed the Company to maintain its production rate.

The Macassa Mill was constructed in 1986, originally designed for a throughput of 725 tonnes per day. The mill underwent additional expansions and was upgraded to handle 2,000 tpd. Processing of ore at Macassa starts with crushing and grinding to a particle size of 45μm before it enters the leach tanks for cyanidation. Then, it flows through a carbon-in-pulp (CIP) circuit, followed by a Merrill-Crow recovery system. The Macassa Mill was constructed in 1986, originally designed for a throughput of 725 tonnes per day. The mill underwent additional expansions and was upgraded to handle 2,000 tpd. Processing of ore at Macassa starts with crushing and grinding to a particle size of 45μm before it enters the leach tanks for cyanidation. Then, it flows through a carbon-in-pulp (CIP) circuit recovery system. The concentrate is melted in an inductotherm induction furnace where doré is poured and typically contains 85% to 88% gold.

Geology & mineralization

The gold mineralization at Macassa is found along breaks or faults, in veins as quartz filled fractures, as breccias and as sulphide rich (pyrite) zones. There are multiple mineralized breaks, named the ‘04, ‘05, No.6, Kirkland Lake Main and the Kirkland Lake North and South branches. The breaks strike N60°E and dip 70-80° south in keeping with the Timiskaming trend. The trend of the gold mineralization in the Kirkland Lake camp conforms to the 60° westerly plunge of the syenite intrusives.

The SMC was a significant discovery, with the zone having a different character than the zones mined historically at Macassa. The SMC is associated with a cross-over structure which links the ’04 / Main Break with the Amalgamated Break. The mineralization trends parallel to the main structures but has a much flatter dip ranging from 20-50° south. SMC mineralization has been found to have greater widths and contain higher grades than the main zones. Considerable potential exists for future exploration drilling to identify additional parallel and stacked zones located above, below and along strike of the known SMC zone.