The holt complex is comprised of three mines (Holt, Holloway and Taylor), all feeding the holt mill for processing.

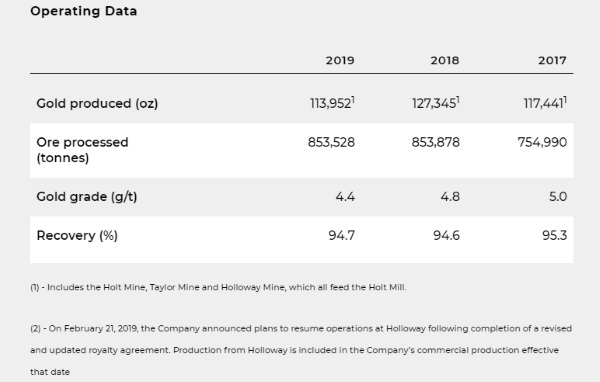

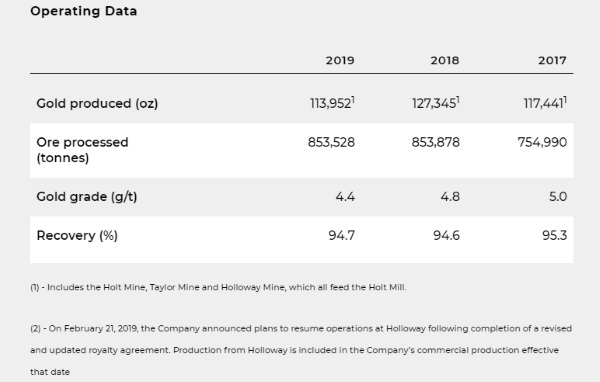

Kirkland Lake Gold obtained the Holt Complex assets through the acquisition of St Andrew Goldfields Ltd. in January 2016. The Holt Mine was built in the late 1980’s by Barrick. In 2019, the mine produced 113,952 ounces of gold, at an average grade of 4.4 g/t. The Holloway Mine was placed on care and maintenance in December 2016. Following the completion of a new royalty agreement, the mine resumed operating in early 2019. The Taylor Mine was commissioned in late 2015. In 2018, the mine produced 58,633 ounces at an average grade of 5.0 g/t.

Quick Facts

|

Location

|

Matheson, Ontario |

|

Mine Type |

Underground, access by shaft at Holt/Holloway, ramp access at Taylor |

|

2019 |

Production |

|

Deposit Type |

Sulphide replacement - Mafic Volcanic at Holt; Fe-tholeiitic mafic volcanic rocks at Holloway; Orogenic greenstone hosted gold at Taylor |

|

Process |

Ore is processed at the Holt Mill (3,000 tpd capacity) |

|

End Product |

Gold doré |

|

Commenced Operation |

Holt (1988), Holloway (1996), Taylor (2015) |

Exploration at Holt Complex

Exploration drilling around the Holt Complex is currently focused on Taylor and Holloway West targets. In the first nine months of 2019, approximately 11,000 metres of surface diamond drilling was completed at Taylor with the main focus being along strike and to depth of current resources at the mine. Results of the drilling are currently being reviewed and will be incorporated into the updated Mineral Resources for the end of 2019.

The Company is planning approximately 43,000 metres of exploration drilling during 2019 on a variety of regional targets at or around the Holt Complex, including the Nighthawk, Golden Highway and Holloway West properties. To the end of September 2019, a total of 38,947 metres had been completed completed.

Mining method and processing

Mining at Holt/Holloway is primarily conducted using Long Hole Stoping with cemented rock fill. A 1.2 km deep shaft provides skipping capacity of 1,500 tpd. Currently, the mining activities at Holt Mine are taking place in Zone 4 in the west, Zone 7 in the East and Zone 6 in the central part of the mine. Mining activities from Zone 7 are now integrated with activities at Holloway with the majority of the ore from this Zone being trucked to Holloway for hoisting. At Holloway, the mine resumed operations in early 2019 after being placed on care and maintenance in December 2016. Mining activities are currently focused on toping in both the Middle and Smoke Deep Zones and development and rehabilitation activities occurring in the historic Lightning Zone.

At the Taylor Mine, mining is currently focused on extracting ore from the 1004 Zone, employing a mix of Long Hole Stoping (60%) and cut and fill (40%) methods. Ore is hauled to surface by a fleet of 45 tonne trucks, averaging a production rate of approximately 600 tpd. Ore from all three mines is processed at the Holt Mill.

The Holt Mill is one of the most efficient gold mills in the region with a capacity of 3,000 tpd. The Holt Mill was constructed in 1988, originally designed for a throughput of 1,360 tpd. Expansions in 1988 and 2001 increased the throughput to 2,500 tpd and 3,000 tpd respectively.

Surface ore storage totals 5,800 tonnes in four bins. Holloway mine has a 1,000-tonne bin, Holt Mine has an 800-tonne bin, and the Mill has a 3,000 and a 1,000-tonne bin. There is a Three stage grinding circuit, gravity circuit, thickener, and a Carbon-in-Leach (CIL) circuit within the plant facilities.

Precious metal stripping is performed in batch. Carbon is transferred to an adsorption column where a Zadra process is utilized as the gold elution method. Barren solution is circulated through two shell and tube heat exchangers and a 360-kW electric inline heater. The resulting pregnant solution is pumped from the solution tank to an electrowinning cell. The gold precipitate is further refined using a 125-kW induction furnace producing Dore’ bars.

Geology & mineralization

The Holt Mine Complex is a mafic volcanic, sulphide replacement hosted gold deposit. The mineralized zones are structurally controlled by both the McDermott Fault and the Ghostmount Fault Zone, which are splays off of the Porcupine-Destor Fault (PDF). Unlike other quartz vein hosted deposits in the region, native gold at the Holt Mine occurs as very fine grains spatially associated with pyrite, typically located in fractures, on grain boundaries, or encapsulated in pyrite grains. Zone thickness can widen from less than 10 metres to locally more than 50 metres. Historically, mined zones include the South (Zone 4), C-104, McDermott, Worvest/Three Star, Mattawasaga, and C-97 zones, which occur over a strike length of three kilometres and have been mined to depths of over one kilometre below surface. More recently, the bulk of the existing gold mineralization is located within Zone 4, Zone 6, Zone 7 and C zones.

The mineralized zones at the Holt Mine display two pronounced shoot plunges: (a) moderate to steep east plunges that outline the major zones, and (b) alignment of zones and small mineralized shoots along shallow west plunging axes.

The Holloway Deposit is hosted by the 30 m to 150 m wide Holloway unit, a south dipping band of Fe-tholeiitic mafic volcanic rocks which is bounded to the north and south facing turbiditic sedimentary rocks and komatiitic ultramafic volcanic rocks, respectively. Mineralization occurs where a 200 m to 300 m wide corridor of east-northeast trending D2-D3 high strain zones obliquely crosses the Holloway unit, resulting in a deflection in its strike to east-northeast trends from east to west-northwest ternds that are more typical at the property scale (Rhys, 2005a). Mineralization in the Holloway Mine comprises the Lightening, Middle and Blacktop zones.

At Taylor, the geological setting can be generalized from south to north consisting of mafic volcanic rocks, which are relatively undeformed and unaltered; ultramafic and mafic volcanic rocks, which vary from weakly to strongly deformed, altered and contain felsic to intermediate porphyritic intrusions of varying shapes and sizes; and then metasedimentary rocks, which are interpreted to represent the footwall of the PDF.

Four mineralized deposits have been identified at Taylor over a strike length of 2 kms. From east to west these are; the Shaft Deposit, with gold mineralization associated with felsic intrusive rocks; the East and West Porphyry deposits, a system of stacked lenses, with the gold mineralization associated with felsic intrusive and altered mafic-ultramafic rocks (Green Quartz Carbonate); and the Shoot Deposit, with gold mineralization hosted by argillaceous metasedimentary rocks within a package of green quartz carbonate ultramafic volcanics.