SICK Ltd

Warehouse and Distribution Centers

Receiving area

• Pallet storage and retrieval

• Automated conveyor loading

• AGV contour navigation in shipping/receiving

• Extendable conveyor loaders

• Forklift automation and safety

• Depalletizer station

Receiving process

• DWS (Dimension, Weighing, Scanning) – vision-based scanning systems

Conveyor safety pulls

• RFID bulk scan in shipping/receiving areas

• Hand-held scanners in the receiving process

• Hand-held scanners for reading 2D codes in the receiving process

• Accumulation conveyor/retrofits

Put away process

• RFID pallet tag reading/writing

• Pallet overhang detection

• Automated pallet storage safety

• Tote fill check and scan

• Empty tote detection

• Pallet detection

• Pallet load profiling

Automatic storage and retrieval systems

• Pallet transfer car

• ASRS alignment and obstruction detection

• ASRS unit load automation

• ASRS unit load fine positioning

Manual warehouse areas

• Vehicle height monitoring

• High bay empty storage confirmation

• RFID bulk scan in shipping/receiving areas

• Forklift anti-collision

• Automatic package/pallet identification from forklifts

• Storage area access control

Cold storage

• Pallet transfer car (cold storage)

• Pallet detection

• ASRS alignment (cold storage)

• Cold storage muting

• Cold storage AGV

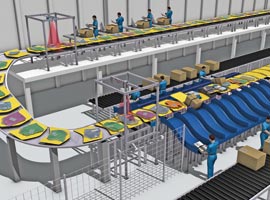

Conveying and storage

• Overhead conveyor collision prevention

• Overhead conveyor safeguarding

• Overhead conveyor guidance and positioning

• Overhang/garment conveyors

• Tote identification and sorting

• Conveyor gapping

• Vertical storage system safety

• Sort conveyor switching

• Vertical storage safety and height detection

Pick process

• Tote picking and case breakdown

• Picking error detection

• Pick station error-proofing

• Pick quantity verification

• Manual pick verification

• Pick-to-light manual picking stations

Sorter applications

Packing and shipping area

• Tilt-tray sorter off load detection

• Tilt-tray singulation verification

• Tilt-tray item identification

• DWS (Dimension, Weighing, Scanning) – vision-based scanning systems

• Automated wrapping machines

• Palletizer profiling and safeguarding

• Stretch-wrapper safeguarding

• AGV safeguarding and reflector navigation

• Area access safeguarding

• Pallet positioning for AGVs

• Tilt-tray singulation verification

Source: http://www.sick.com/mi/ca/home/solutions/industries/warehouse_and_distribution/Pages/warehouse_and_distribution.aspx

Magazine

No information