Holt Mill

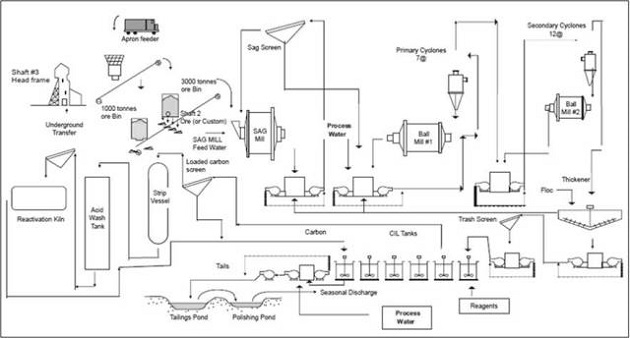

The Holt Mill was constructed in 1988, originally designed for a throughput of 1,360 tpd. Expansions in 1988 and 2001 increased the throughput to 2,500 tpd and 3,000 tpd respectively. Surface ore storage totals 4,900 tonnes in three silos. There is a grinding circuit, two cyclone cluster circuits, a thickener, and a Carbon-in-Leach (CIL) circuit within the plant facilities.

Precious metal stripping is performed in batch. Carbon is transferred to an adsorption column where a Zadra process is utilized as the gold elution method. Barren solution is circulated through two shell and tube heat exchangers and a 360 kW electric inline heater. The resulting pregnant solution is pumped from the solution tank to an electrowinning cell. The gold precipitate is further refined using a 125 kW inductotherm furnace.

The Holt Mill was re-commissioned in September 2009, ahead of production from the Holloway Mine as the Company entered into a custom milling agreement with a nearby producer. Since such time, ore from Holloway, Hislop and now the Holt Mine is being shipped to the mill for processing, and the mill is at full capacity.

Source: http://www.sasgoldmines.com/s/HoltMill.asp

|