Sudbury Lime Ltd.

Process & Facilities

Consistent Quality = Reliable Results

Our plant is one of North America's only stand-alone facilities designed specifically to transform quicklime into high calcium lime slurry at a commercial scale. Our capacity is approximately 100,000 tons per year (CaO).

Getting the Sinest Grind – Here's how We Do it:

• Our sophisticated, automated process control monitors by temperature and adjusts for varying factors, such as hard-burned limestone, that would usually affect output consistency.

Getting the Sinest Grind – Here's how We Do it:

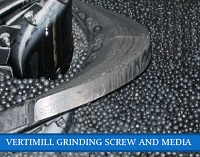

| High Efficiency Vertical Grinding Mill |

Recirculating Tank

|

Hydrocyclone |

|

|

|

| The Vertimill VTM-150 Grinding Mill Slaker allows for longer retention and considerable recirculation of product for secondary grinding and slaking. | Gravity separates larger material for regrinding. | Centrifugal force removes remaining heavier materials and recirculates them – virtually eliminating the possibility of grit entering into product storage tanks. |

Accuracy You Can Rely On

• Our sophisticated, automated process control monitors by temperature and adjusts for varying factors, such as hard-burned limestone, that would usually affect output consistency.

• An extremely high level of QA/QC testing – both internal and external.

• Highly-controlled processes enable adjustment of product densities as needed.

• Experienced operators are onsite daily to oversee conscientious housekeeping procedures and ensure quality control.

Source: http://www.sudburylime.ca/facilities.php

|