Specially Rolled Plates

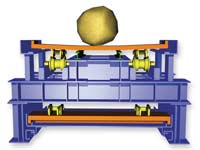

The plate feeder's continuous loading surface, illustrated in orange, is constructed from a series of short plates fixed individually to the caterpillar chain.

These plates are manufactured from MMD designed specially rolled sections. The manufacturing process of these rolled sections provides tighter measurement tolerances, increased wear properties and greater resistance to impact loads than is possible with casting techniques. The close toleranced overlapping edges prevent spillage in between the plates, even in the most exposed areas around the head and tail sprocket.

The ribbed design on the plates optimises surface area and promotes a positive grip on the material, whilst also providing a lightweight yet strong surface to load onto. The ribbed construction also enables the bolts attaching the plates to the chain links to be positioned in the deep recesses of the ribbed plates, protecting the bolts from damage from loading material. The bolted construction allows small sections of plates to be removed easily in order to access and maintain components on the plate feeder.

The strength of the conveyor plates is not only achieved through the design and manufacturing process of the plates, but also by the positioning of the chains and the impact rails, which, as well as supporting the plates also give them the flexibility to deform within their elastic limit providing a strong impact cushion for loading material. Because of the apron plates deflection properties, severe impact loads dumped onto the feeder are mostly transmitted to the robust mainframe through the solidly mounted impact rails, preventing impact damage to the rollers and chain thereby prolonging the service life of these items.

The strength of the conveyor plates is not only achieved through the design and manufacturing process of the plates, but also by the positioning of the chains and the impact rails, which, as well as supporting the plates also give them the flexibility to deform within their elastic limit providing a strong impact cushion for loading material. Because of the apron plates deflection properties, severe impact loads dumped onto the feeder are mostly transmitted to the robust mainframe through the solidly mounted impact rails, preventing impact damage to the rollers and chain thereby prolonging the service life of these items.

Source: http://www.mmdsizers.com/products/feeder/features/plates.php

|