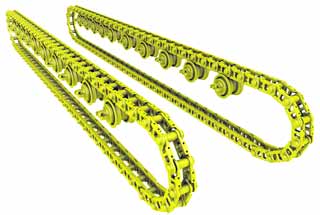

Chains

|

MMD Plate Feeders feature two strands of heavy duty chain with a sealed and lubricated hardened steel construction. The process of hardening each part of the assembly is controlled to produce the ultimate in toughness and resistance to shock, as well as maintaining uniformed wear throughout the parts long service life.

|

Chains and |

Carry and Return RollersThe top carrying rollers are a standard tractor type, spaced at intervals along the length of the feeder, to ensure smooth travel of the deck during operation. In the loading zone the rollers are tightly spaced together, providing extra strength and support to take care of the undefined impact loads in this area. The bearings on the carrying rollers have been engineered to accept high impact loads and they are sealed for lifetime lubrication and extended wear life. |

Carry Roller |

| The return strand of the feeder is carried back on specially heat treated steel return rollers. The rollers are bolted onto the lower joist, and the whole return roller assembly can be simply withdrawn through a hole in the web of the joist facilitating easy removal and installation from the side of the feeder. |

Return Roller |

Source: http://www.mmdsizers.com/products/feeder/features/chains.php

|