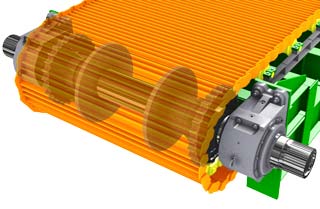

Head and Tail Shafts

|

| Plate Feeder Head Shaft |

The MMD Apron Plate Feeder has a heavy duty head (drive) and tail (driven) shaft machined from high grade hot rolled steel. Each shaft is accurately machined to accept the sprocket hubs, bearing assemblies, and on the head shaft, the support rings and the drive unit.

The support rings on the head shaft are positioned in-line with the impact rails and support the apron plates as they travel around the head shaft.

The tail shaft having no drive, is contained between the shaft bearing assemblies and is therefore shorter and lighter than the head shaft.

Large bearings are used on both the drive and tail shafts. They are designed to be grease lubricated and have a reservoir for grease in the bearing blocks and end caps.

Sprockets and Hubs

|

| Sprocket and Hub |

The sprockets on the head and tail shafts are bolt on segmented design made of a wear resisting alloy steel. All sprocket tooth segments, for both tail and head sprockets are interchangeable for easy maintenace and spare parts ordering. Each sprocket has an odd number of teeth on each wheel, thereby contact with all of the teeth is only completed after two revolutions of the chain for a longer service life.

The sprocket tooth segments are bolted onto hubs with high tensile bolts for ease of replacement. The sprocket hubs are accurately machined from alloy to transmit the high torque loads required to “Pull-out” from a fully laden start up.

Source: http://www.mmdsizers.com/products/feeder/features/sprockets.php

|