CD Industrial Group Inc.

Blast Hole Drills

Event Details

LEVEL II

3 DAY

$1895

INSTRUCTOR-LED COURSE

Learn to:

Interpret complex blast hole drill schematics

Test for correct pump flows and relief pressures

Verify normal and faulted travel/propel systems

Describe counterbalance functions and tests

Measure valve piloting signals and pressures

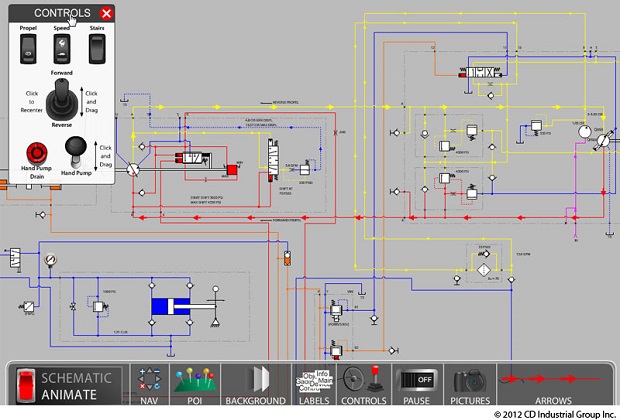

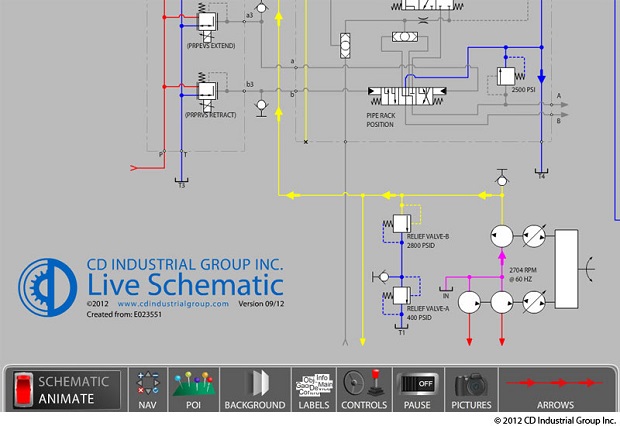

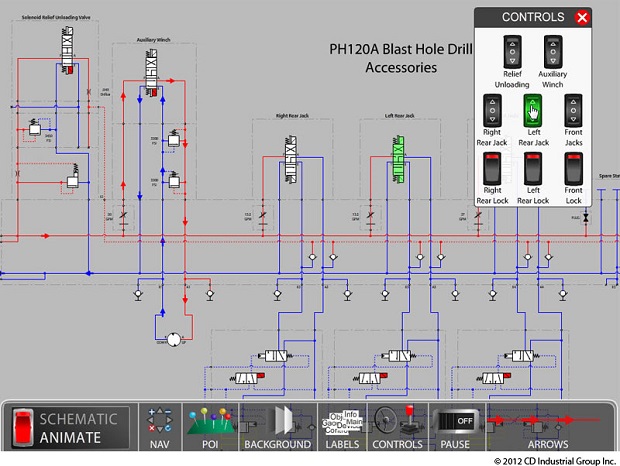

In this customized course, mine mechanics, millwrights, heavy equipment technicians, team leaders, planners and reliability specialists learn the hydraulic systems in use on Bucyrus 49HR (now Caterpillar MD664) and P&H 120A blast hole drills. On-screen simulations and Live Schematics bring the systems to life for intensive and rigorous training.

Participants learn to maintain and troubleshoot blast hole drill systems for maximum availability. A method of analysis for determining faults based on "knowing what normal is" will be taught taught along with our Ten Step Troubleshooting Process. Schematic reading and safe work practices are core topics throughout.

Travel Circuitry

Objective: Explain the functions of a closed loop propel system

Activities: Diagnose typical hydrostatic system problems

Know the undercarriage hydraulic functions cold

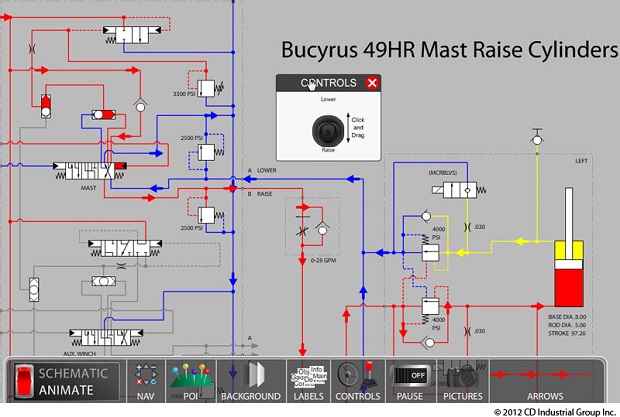

Mast Raise and Lower Functions

Objective: Identify the components of the mast raising circuits

Activities: Test valve piloting functions and port relief settings

Solidify your skills with counterbalance valves

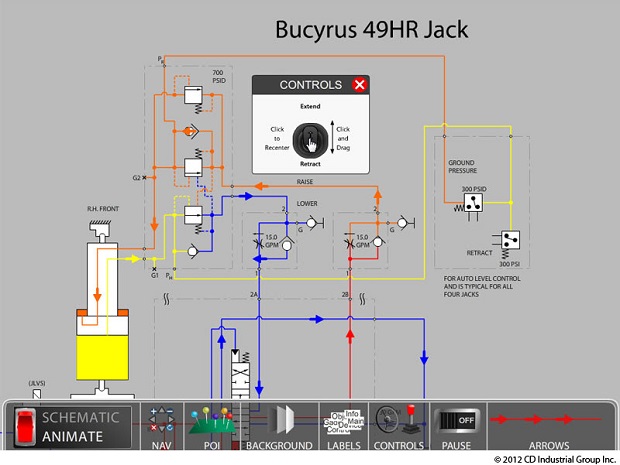

Jack Cylinder Circuits

Objective: Identify the components and their functions in the jack cylinder circuits

Activities: Diagnose auto-level malfunctions

Decode the mysteries of pressure compensated flow controls

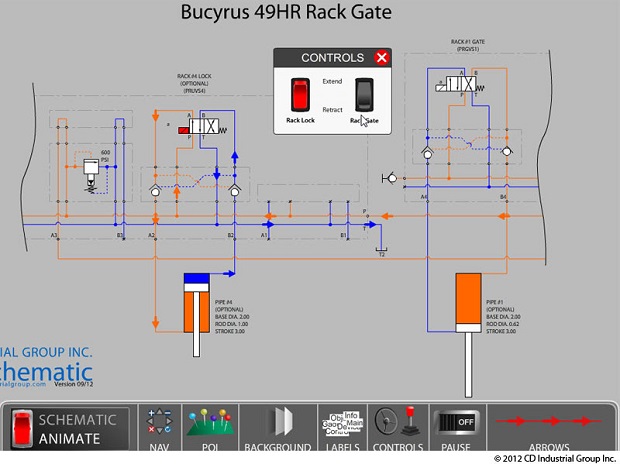

Pipe Rack Position Cylinders

Objective: Describe functions of components on the pipe rack position circuits

Activities: Test counterbalance settings and confirm valve pilot pressures

Know the six-port, two-position selector valves cold

The Hydraulic Power Unit

Objective: Identify pump types and system pressure relief and unloading valves

Activities: Design pump volumetric and load tests to aid in troubleshooting

Know the key maintenance principles for long pump life

Auxiliary and Accessory Systems

Objective: Interpret auxiliary systems and circuit designs

Activity: Identify schematic paths for auxiliary winch, pin locks, dust seals and dust curtains

Know your grease and lube systems cold

Want to book this course? Get in touch:

1·866·628·3224 info@cdiginc.com

CD Industrial Group Inc.

CD Industrial Group Inc. is an industrial training company. Our e-learning site is www.lunchboxsessions.com. Our interactive hydraulics training is based on over fifteen years of direct classroom testing. It gets the learner inside the system. Customized, instructor-led training and on-site maintenance team coaching is also available in a variety of mechanical and electrical topics.

When

September 13, 2020 - September 13, 2025

Add this to my calendar

Outlook

GOOGLE

Yahoo

iCal