Home >

Supplier Companies >

CD Industrial Group Inc. >

Events >

Hydraulic Shovel Maintenance and Troubleshooting

CD Industrial Group Inc.

Hydraulic Shovel Maintenance and Troubleshooting

Event Details

LEVEL II

6 DAY

INSTRUCTOR-LED COURSE

Learn to:

Use complex schematics as a troubleshooting tool

Verify correct functioning of shovel hydraulic circuits

Develop a reliability based approach to system maintenance

Prepare a methodical troubleshooting "battle plan" in advance

In this course, technicians, mechanics, and reliability specialists learn to identify the major hydraulic circuits on a mining shovel. With a careful examination of major pump groups, pressure controls as well as pilot and directional valving, participants learn to verify correct and normal hydraulic shovel functions.

Participants move forward with knowledge of correct functions and settings as well as reliability based maintenance practices for fluid cleanliness, temperature, and leak control to conduct logical fault finding as a team. A method of analysis for determining faults based on "knowing what normal is" will be taught taught along with our Ten Step Troubleshooting Process. Schematic reading and safe work practices are core topics throughout.

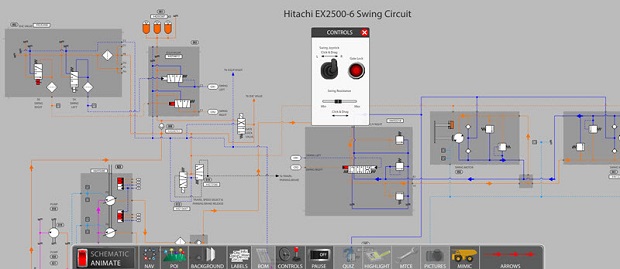

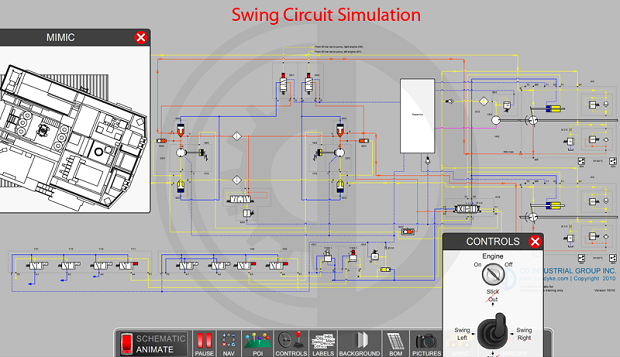

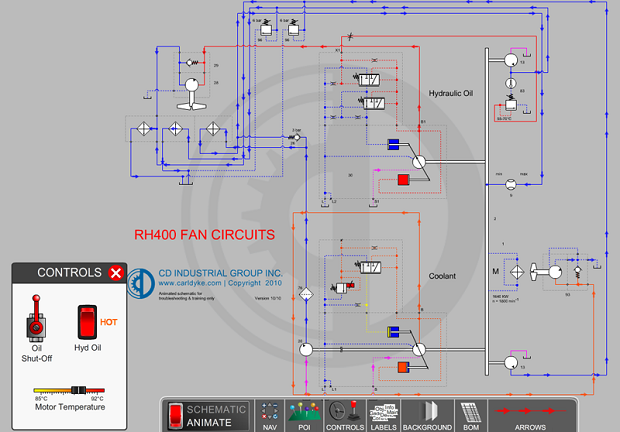

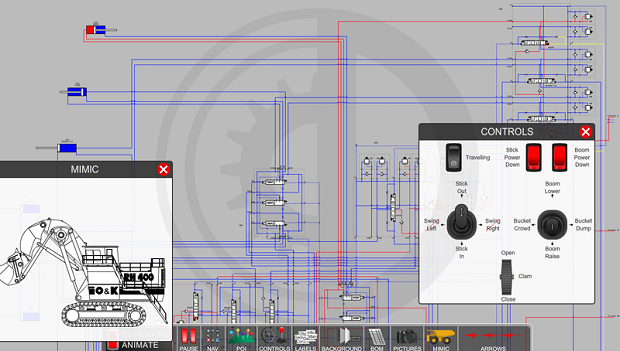

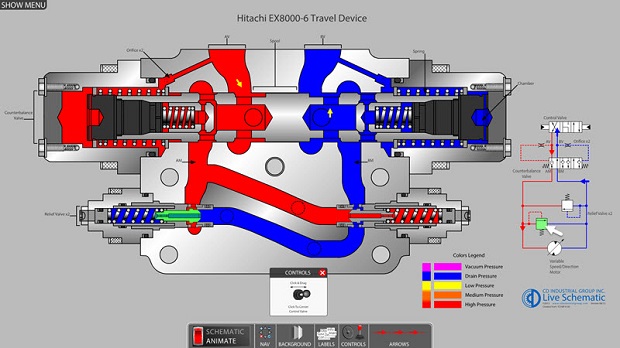

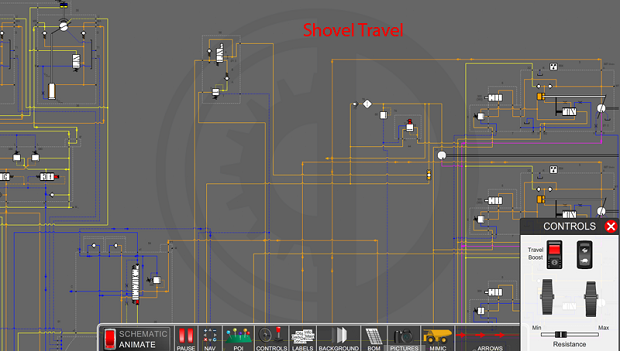

This extensive eight-day course is taught with live hydraulic circuit training panels (like the ones shown here), troubleshooting simulation software, on-machine exercises, and through instructor guided, hands-on study of valves. On-screen simulations and Live Schematics bring the systems to life for intensive and rigorous training. We can build and deliver a training program specific to the model of hydraulic shovel you use.

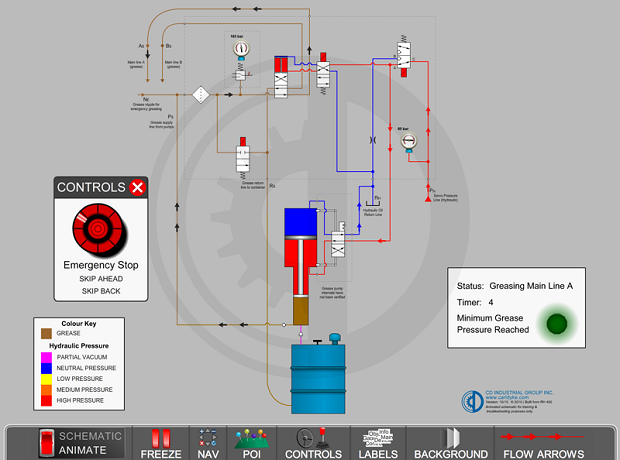

Greasing System

Objective: Explain the grease circuit functions and programmed cycles

Activities: Test for basic functions and performance in the greasing system

Learn the features of common grease pumps, injectors and distributors

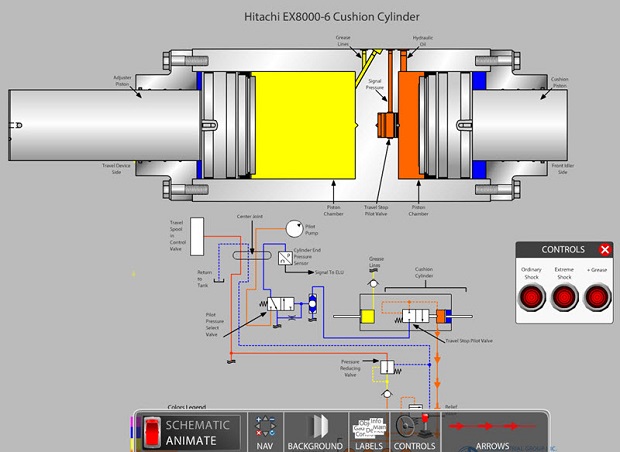

Track Tension and Cushion

Objective: Describe the track tension and cushion cylinder circuit

Activities: Identify hydraulic flow paths for ordinary and extreme shock

Learn to detect depleted accumulators and relief valves stuck open

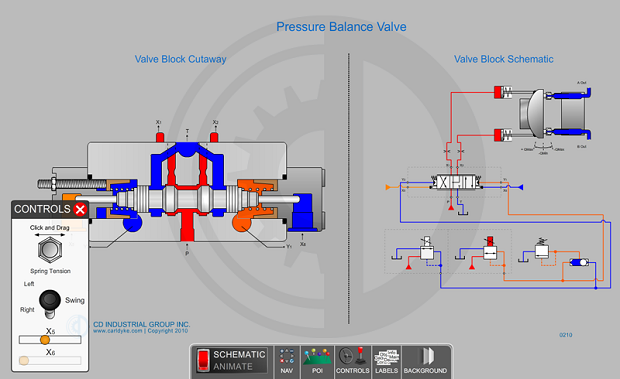

Pilot Circuit

Objective: Identify the components and functions of the servo and pilot circuits

Activities: Test pressure controls and electro-hydraulic proportional valves

Solidify your knowledge of pump piloting with pressure reducing valves

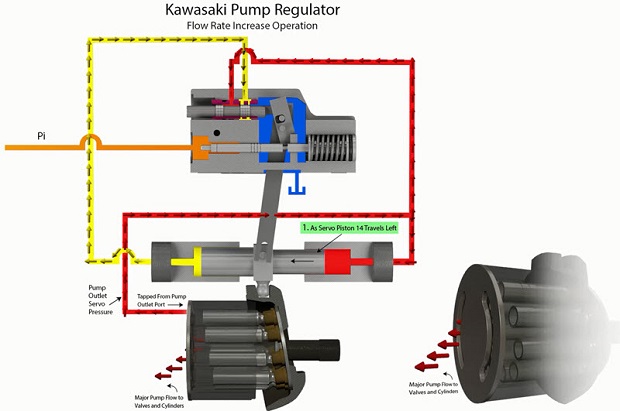

Pump Regulator

Objective: Describe the functions of the pump regulator

Activities: Identify specific pilot ports and pilot actions

Use our 3D sequences to learn your Kawasaki pump regulator functions cold!

Open Loop Swing Drive

Objective: Interpret open-loop swing systems

Activity: Test for correct electrical pilot signals and pilot pressures

Know your EHC and DQR and port relief valve functions

Closed Loop Swing Drive

Objective: Interpret closed-loop swing systems

Activity: Test for correct servo, charge pressure and flushing functions

Know your over-running mass controls and single engine modes

Cooling Fan Drive Circuit

Objective: Verify correct thermal valve triggering of cooling circuits

Activities: Adjust pump controls and valving to achieve correct fan speed

Work with the flywheel effect of large diameter fans

Attachment Circuit

Objective: Interpret attachment pilot and directional valve schematics

Activities: Learn to test for load holding check valve and float problems

Confirm the role of port relief and anti-cavitation valves

Travel Valve

Objective: Describe the functions of the travel valve

Activities: Identify counterbalance and port relief functions

Detect cross-port relief valves stuck open

Undercarriage Travel - Propel Circuit

Objective: Explain propel circuit paths and functions

Activities: Diagnose and solve motor and counterbalance problems.

Learn how the pump management system limits engine torque requirement

Want to book this course? Get in touch:

1·866·628·3224 info@cdiginc.com

CD Industrial Group Inc.

CD Industrial Group Inc. is an industrial training company. Our e-learning site is www.lunchboxsessions.com. Our interactive hydraulics training is based on over fifteen years of direct classroom testing. It gets the learner inside the system. Customized, instructor-led training and on-site maintenance team coaching is also available in a variety of mechanical and electrical topics.

When

September 13, 2020 - September 13, 2025

Add this to my calendar

Outlook

GOOGLE

Yahoo

iCal