Pump Shell CTI Reline Rreduces Cost of Operation Up to 50%

Challenge

Clarabelle Mill was incurring expensive part replacement costs in order to maintain their onsite slurry pumps and could experience extended lead time of up to 16 weeks for OEM parts.

Engineered Solution

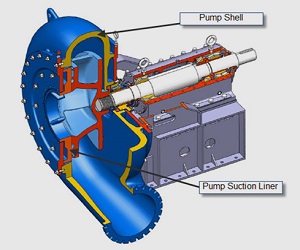

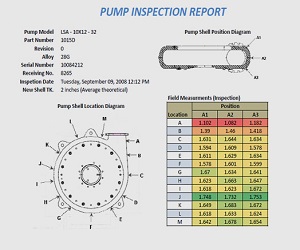

By reclaiming the worn pump shell and suction liners, we are able to overhaul the part with our award winning ceramic matrix lining in order to restore the pump to near original condition. To ensure pump shell remain structural adequate for relining, a detailed inspection report is generated at each repair cycle reducing the possibility of part failure in the field. The process of recycling a used part using the patented ceramic lining can be accomplished within 2 weeks ensuring the customer is not left without supply and minimize possible downtime. Vale has seen shells relined over 6 times resulting in direct cost saving of over 50% in comparison of OEM part replacement while still maintaining the performance expected during the service life of the part.

Technology Utilized

• CTI patented process

• Award winning ceramic matrix lining

• Superior adhesion technology ensuring proper matrix bond during service life of part

Results

• Dramatic reduction of cost as high as 50% during the useful life span of the part

• Reduced lead time requirements to obtain part

• Proven to meet extend OEM part wear life

Source: http://www.carriereindustrial.com/case-study/pump-shell-cti-reline-reduces-cost-of-operation-up-to-50/

- 3 years to less than 5 years

- Specific SkillsStart up, shut down, adjust and monitor robotic welding production line; Operate manual or semi-automatic flame-cutting equipment; Operate manual or semi-automatic, fully automated welding equipment; Maintain and perform minor repairs on welding, brazing and soldering equipment; Interpret welding process specifications; Fit, braze and torch-straighten metal; Operate oxygen arc cut