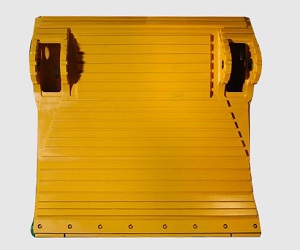

CIS Triples The Service Life of 28 m³ Face Shovel

Challenge

Lac Des Iles Mines was experiencing short service life of their Komatsu PC 5500 face shovel. The mine had to pull the unit from production frequently in order to rebuild the shovel which resulted in poor productivity and machine availability.

Engineered Solution

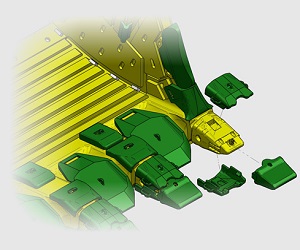

By studying the wear patterns and using superior wear products, CIS was able to reduce the overall bucket weight by 3,400 lbs and increase wear life from 3 months to 9 months in the field. Not only was the client able to used the unit 3x longer, they were also able to load 2.8% more material every bucket cycle in the shovel which increased production tonnages during its service life. The 3-piece hammerless Posilock tooth system is designed specifically for large hydraulic face shovels and clients benefit from the quick point replacement in the field to minimize downtime.

Weight Reduction

• Reduced shovel weight from 120,466 lbs to 117,034 lbs

• Weight reduction equates to a 2.8% reduction allowing for more material to be moved

Extended Field Service Life

• Using best in class material resulting in extended service life

• Customer experience 3 times wear life of the shovel after applying CIS wear package

Replaceable Tooth System

• 3-piece hammerless sidewinder pin system

• Strong positive lock requires no adjustment during normal adapter life

• A wide selection of point shapes available to match any application

Source: http://www.carriereindustrial.com/case-study/cis-triples-the-service-life-of-28-m-face-shovel/

- 3 years to less than 5 years

- Specific SkillsStart up, shut down, adjust and monitor robotic welding production line; Operate manual or semi-automatic flame-cutting equipment; Operate manual or semi-automatic, fully automated welding equipment; Maintain and perform minor repairs on welding, brazing and soldering equipment; Interpret welding process specifications; Fit, braze and torch-straighten metal; Operate oxygen arc cut