BSL Casting

BSL Casting Completes a Key-in-Hand Retro-Engineering Project

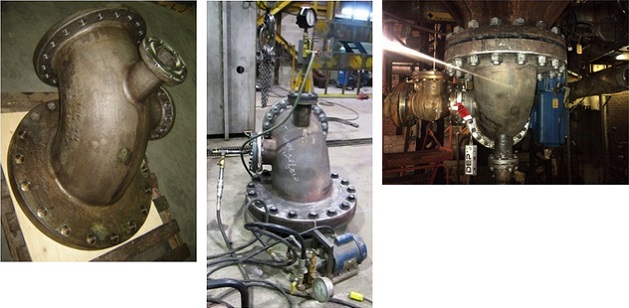

One of our engineering partners had a pulp & paper customer who was forced by the compensation board inspector to change 2 units of 90 years-old big digester elbow due to cracks on the surface being a possible danger for their employees.

A few issues arose. First, components of that age were not made according to any ASME boiler & pressure vessels standard. So, the new parts needed to meet such standards.

Moreover, the part couldn’t be removed until a shutdown period was planned otherwise all the production would have stopped, resulting in a major loss in profit.

Our engineering partner had to scan the part on site and proceed to complete FIA analysis to make sure the calculations were done correctly to meet the pressure vessel standards.

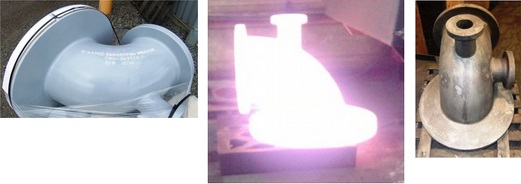

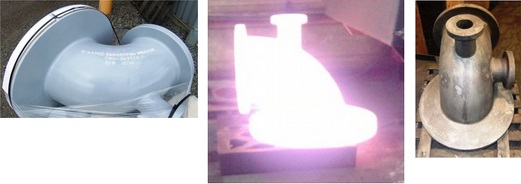

Once the drawing was completed and approved by the according provincial boiler & pressure vessels act regulation agency, BSL Casting could initiate the manufacturing process in 4 stages :

Pattern-making : we had to have our pattern-maker supply a scanned inspection prooving that the pattern was exactly to required dimensions as installation required tight tolerances.

Source: http://www.bslcasting.com/en/news.html