Home >

Supplier Companies >

Machines Rogers International Inc >

Articles

> Specifications: V-30 Boring...

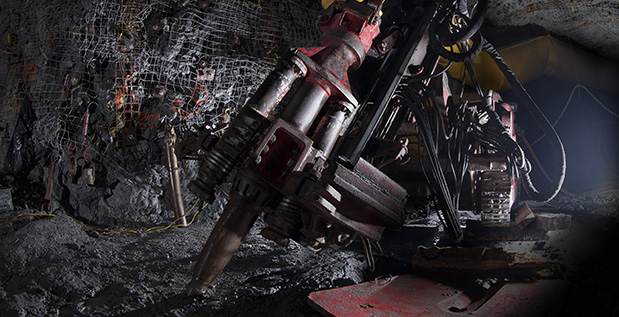

Machines Rogers International Inc

Specifications: V-30 Boring Head

The V-30 Boring Head was designed to drill large diameter holes efficiently and safely.

Machines Roger International maintains a strategic alliance with the drill manufacturer Sandvik from Winnipeg that develop an ITH drill (formerly Cubex) adapted to the use of the V-30.

The V-30 can meet many diversified drilling requirements and can drill in various types of rocks. It can even go through the hardest minerals. The V-30 can be used in three methods of drilling with angles of 45 to 90 degrees; the Conventional pulling method, the Blind boring pushing method and the Down reaming pushing method.

The V-30 Boring Head can be used to accomplish a variety of underground works

• Slot raises

• Drain holes & service holes

• Electrical cable holes

• Ore and waste passes

• Ventilation raises

The V-30 can be used in three methods of drilling

1. Conventional V-30 drilling

This drilling method is used with the conventional V-30 drilling head. A 6.5 in. (165 mm) pilot hole is drilled to the target on the lower level. The pilot hole is reamed to 10 in. (250 mm). The V-30 drilling head is then attached and is pulled to the upper lever.

2. Blind boring method

The blind boring method is used when the upper level is difficult or impossible to access, such as in pillar remnants. After having drilled the 6.5 in. (165 mm) pilot hole and reamed to 10 in. (250 mm), the V-30 head is attached and pushed to the

upper level.

3. Down reaming method

Down reaming is the most commonly used method of V-30 boring. Using this method of drilling, no employee is required on the lower level to attach the equipment or to change the bits. After the drilling of the 6.5 in. (165 mm) pilot hole and reamed to 10 in. (250 mm), the V-30 is attached and pushed to the lower level.

Consult (pdf)

Consult (pdf)

Magazine

No information