SICK Ltd

Beverage

Achieve operational efficiency and reduce costs on your beverage production lines with solutions from SICK.

Stringent hygienic conditions in beverage production place tough challenges on automation solutions. Products from SICK are engineered to last – they are resistant to impact, vibrations, and aggressive detergents while offering maximum precision and reliability, even at high throughput rates. Solutions from SICK are user-friendly, ensuring reduced machine downtime during product changes.

Filling

Focus applications:

• Transparent bottle detection

• Liquid level monitoring in tank

• Pressure monitoring

• Temperature monitoring

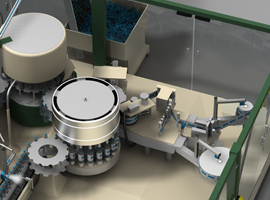

Capping

Focus applications:

• Transparent container detection

• Quality control of capping

Labeling

Focus applications:

• Detecting label placement position

• End of label film roll detection

Packaging

Focus applications:

• Verifying completeness of bundles before wrapping

• Flexible print mark detection

Palletizing

Focus applications:

Entry/Exit in palletizing

Stretch wrapping machines

Focus applications:

Entry/Exit in stretch wrapping machines

Conveyor systems

Focus applications:

Measuring conveyor speed

Source: http://www.sick.com/mi/ca/home/solutions/industries/beverages/Pages/beverage11.aspx

Magazine

No information