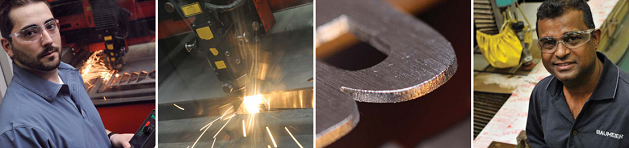

Baumeier Corporation

Waterjet & Laser Cutting

Shape Cutting Equipment Capabilities:

Dynamic Waterjet

Designed to eliminate edge taper, Dynamic Waterjet with Active Tolerance Control, is an advance motion, 3D kinematics system that provides tilt control to cut parts faster and with greater accuracy. Jobs requiring a higher degree of precision on corners will benefit from this advanced Waterjet cutting technology. Similar to conventional waterjet machinery, it can be used on a broad range of material.

Specifications:

• Standard cutting table of 6x12 feet

• Accuracy of +/- 0.003 inches

• Repeatability of +/- 0.002 inches

• Speed up to 2,000 ipm

• Flowmaster control system

• Z – Axis adjustability of 9.8 inches

• Cutting pressure up to 60,000 psi

Conventional Waterjet

Using a variety of water and abrasive mixtures under high pressure, conventional waterjet cutting is used for the metal cutting and shape cutting of a broad range of material. Material that can be cut with a high degree of precision includes film, foam and cardboard to stainless steel and granite, with a thickness ranging from 0.001 to 10 inches. Material loss is minimized because complex computer programs produce the most efficient layout and cut widths are small, ranging between 0.01 and 0.05 inches.

Specifications:

• Standard cutting table of 6x12 feet

• Accuracy of +/- 0.003 inches

• Repeatability of +/- 0.002 inches

• Speed up to 1,200 ipm

• Flowmaster control system

• Z – Axis adjustability of 10 inches

• Cutting pressure up to 55,000 psi

Laser

The CNC laser cutting process is designed to cut a variety of materials to precise specifications. Advanced laser cutting software programs guarantee the most efficient layout of material. The material lies stationary on the cutting table while the laser beam is guided through mirrors from the stationary laser resonator to the moveable cutting head. A precise cutting operation is produced because the distance between the cutting nozzle and the work piece is automatically held constant. The shape cutting equipment, by design, adjusts power and cutting speeds based on the complexity and type of material being cut.

Specifications:

Standard cutting table of 4x10 feet

Accuracy of +/- 0.005 inches

Repeatability of +/- 0.002 inches

Control system – Bysoft CNC programming software and Bynest mutipart nesting software

Z – Axis adjustability of 2.75 inches

Maximum work piece weight of 1,125 lbs.

Source: http://www.baumeier.com/cutting-shape-cutting-equipment-capabilities.html

Junior Machinist / CNC Machine Operator

We are specifically looking for a junior machinist or a machine operator with 2 years of experience in the machining field, who is willing to learn and grow with the company.

Laser Operator

- Review, interpret and process work orders and part drawings.

- Set up and operate Laser.

- Perform first-off and in-process inspections of all parts produced

Welder/Fitter

- Must have a minimum of two years of welding/fitting experience in a custom fabrication environment.

- GTAW (TIG) experience of mild and stainless steels required with GTAW of aluminum and GMAW (MIG) of mild and stainless steels. Preference given to CWB certified applicants.