Alamos Gold Inc

Island Gold Mine

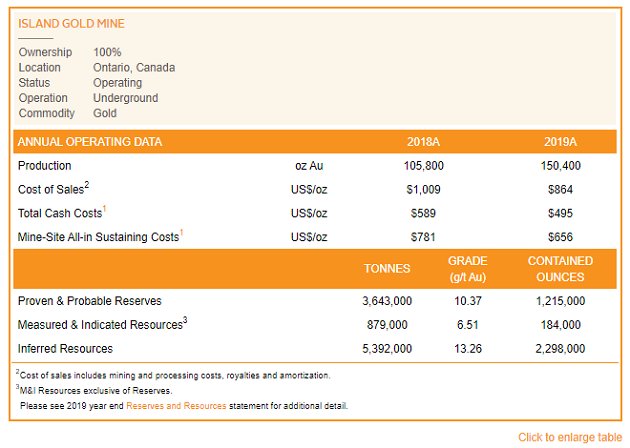

Island Gold is a long-life, high-grade, low-cost underground gold mine located in Ontario, Canada. The operation is undergoing an expansion which will drive production higher, costs lower and strong free cash flow growth.

OVERVIEW

The Island Gold mine is a long-life operation with a large mineral reserve and resource base that has grown significantly since 2015 through ongoing exploration success. A Phase I expansion of the operation was completed in 2018 taking underground mining and milling rates to 1,100 tpd. This helped drive production to a new record of 150,400 ounces of gold in 2019, the fifth consecutive year of record production. The Phase II expansion to 1,200 tpd was permitted in mid-2019 and a Phase III expansion study is expected to be completed during the first half of 2020.

LOCATION

The Island Gold Mine is located 83 kilometres northeast of Wawa, Ontario. The mine comprises 217 patented, leased and staked claims covering 7,926 hectares. It is accessible via a four-season road from Highway 519, just west of the town of Dubreuilville.

HISTORY

In 1985, drilling approximately two kilometers south of the Kremzar Mine intersected a series of sub-parallel lenses containing gold mineralization within deformed rocks of the Goudreau Lake Deformation Zone (gldz). These lenses are known as the Lochalsh, Island Gold, Shore, and Goudreau Lake Zones. Over 1989 and 1990, underground access was established into the Island deposit with an adit from the north shore of Goudreau Lake. A bulk sample weighing 4,167 tonnes was extracted and processed at the on-site Kremzar Mill.

Encouraging results were obtained from exploration work conducted from 1996 to 2002 and, in 2004, an exploration program was initiated in order to complete a resource estimate. On January 1, 2005, Richmont Mines became the operator of the project. The project began commercial production on October 1, 2007. Richmont acquired Patricia Mining’s 45% interest in December 2008, becoming 100% owner of the property and operations.

Exploration activities ramped up in 2009 with a minimum of 30,000 metres of drilling completed in each of the next several years, increasing sharply to more than 80,000 metres in 2012. This included drilling below the 400 metre level as part of the Island Gold Deep program which resulted in the discovery and initial inferred mineral resource on the high grade deep C Zone in January 2013. Over the next year, drilling in the Island Gold Deep sectors from the west, below Lochalsh, to the east and below Extension 1 confirmed the presence and continuity of the deep C Zone and some parallel zones. This drove a substantial increase in inferred mineral resources to 3.6 million tonnes grading 9.07 g/t for 1.04 million ounces of gold as of April 2014. This represented an increase of nearly one million ounces at a 46% higher grade from the end of 2012.

Ongoing exploration success continued to add higher grade inferred mineral resources over the next few years while a large portion was converted to mineral reserves. As of the end of 2019, mineral reserves had increased 62% in terms of ounces and 13% in terms of grade since the acquisition of Island Gold in November 2017.

GEOLOGY AND MINERALIZATION

The property lies within the Michipicoten greenstone belt, which is part of the Wawa subprovince and Superior province of Archean age. The Michipicoten greenstone belt is approximately 140 km long by 45 km wide. The property is stratigraphically positioned in the upper portion of the Wawa Assemblage capped by pyrite-bearing iron formation outcropping in the Morrison and Pine zones.

A 30 km long and 4.5 km wide northeasterly trending, structurally deformed zone, called the Goudreau Lake Deformation Zone (GLDZ), occurs between the two assemblages. Including its subsidiary splays, the GLDZ is believed to be the main control on gold mineralization for the area. East-northeast striking, steeply dipping, sub-parallel zones of gold mineralization are present within the quartz sericite-pyrite-carbonate alteration of the GLDZ. North trending diabase dikes crosscut all stratigraphy.

MINING AND PROCESSING

Island Gold’s underground operations are accessed via a ramp system. The primary mining method is longitudinal retreat long-hole stoping. Ore is hauled by truck to the Kremzar mill located approximately 0.8 km from the portal of the ramp.

Ore is processed through a traditional gold mill using a conventional Carbon in Pulp (“CIP”) process, with circuits for crushing, grinding, gold cyanidation and two electrowinning (“EW”) cells. As part of the expansion to 1,100 tpd, the grinding circuit within the mill was upgraded, primarily through the addition of another ball mill.

Source: https://www.alamosgold.com/mines-and-projects/producing-mine/island-gold-canada/default.aspx

|

Development Boomtruck Operator

- Safely move material as directed. Report and document all material moved accurately to his/her Supervisor;

- Accurately report to supervisor the material needed in storage areas U/G

Rock Breaker Operator

- Operate rock-breaker;

- Perform pre-op and post-op inspections on equipment

Scissordeck Bolter

- Install ground support as per company standard;

- Install and maintain services;

- Load development rounds

Ground Control Engineer

- QAQC of shotcrete, ground support installation, grouting, ground support auditing and paste fill;

- Document inspections of underground stoping and development;

- Rock mass characterisation and classification

Mine Engineer

- Assist with blast improvement investigations;

- Look for opportunities to improve efficiencies;

- Provide guidance to EIT’s

Construction Miner - Transmixer

- Operate equipment such as transmixer and shotcrete sprayer;

- Assist in installation, modification and repairs of UG infrastructures

Geological Technician/or Junior Geologist

- 3D digitizing of underground geological mapping and integration into 3D mining software.

- Digitize geological surface geological mapping lithology, structure and mineralization

- Digitize chip sampling of ore development headings as required

Mill Operator/Labourer

- Works and ensure all workers work in compliance with the Occupational Health & Safety Act, Regulations for Mines and Mining Plants and all other applicable government standards and regulations;

- Adheres to and enforces all safety and environmental considerations

Document Control Coordinator - Phase III

- Implement document and data management solutions with a primary focus on workflow, document control, information security and records management.

- Provide ongoing training and support to end users in the use of the document management system.

- Ensure project and operations teams comply with the document management requirements and procedures

Project Controls Manager - Phase III

- Development and implementation of project controls systems and procedures.

- Working with accounting personnel to ensure accurate reporting and approval of accruals, forecasts, and project status.

- Early identification and notification of deviations and variances to project baseline schedule and spend