Alamos Gold Inc

Mulatos Mine

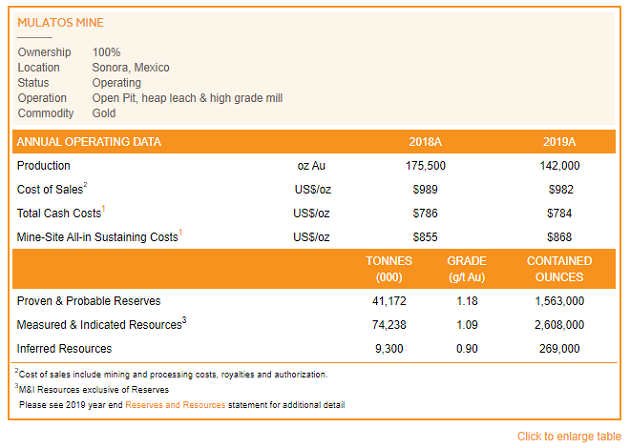

Our Mulatos Mine is our foundation having been acquired for $10 million in 2003 and grown to become a consistent gold producer and significant cash flow generator. To date, Mulatos has generated approximately $420 million in free cash flow.

OVERVIEW

The 100% owned Mulatos Mine is a conventional open-pit, heap-leach operation with gold recovered through a carbon-in-column circuit. The project was originally contemplated as a 10,000 tpd operation though through various expansions and productivity improvements over the years, today operates at a throughput rate of over 20,000 tpd.

Based on Proven and Probable Mineral Reserves at the end of 2019 and current throughput rates, Mulatos has an expected mine life of approximately six years.

In 2019, the Company achieved another major milestone, producing its two millionth ounce at Mulatos, marking the end of the 5% NSR royalty at Mulatos after which no third party royalty is payable on production at the mine.

LOCATION

The Mulatos Mine is located within the Salamandra Concessions in the Sierra Madre Occidental mountain range in the east-central portion of the State of Sonora, Mexico. The mine is approximately 220 kilometres ("km") by air east of the City of Hermosillo, and 300km south of the border between the United States of America and Mexico. The Salamandra Concessions are 100% owned by Alamos and consist of 30,356 hectares of mineral concessions, in 44 discrete concessions. These cover the Mulatos deposit, the satellite gold systems known as Cerro Pelon, La Yaqui, El Realito, El Carricito, El Halcon, Las Carboneras, El Jaspe, Puebla, Los Bajios, and La Dura, and other prospective exploration targets. Mineral rights for all the Salamandra Concessions are controlled by Minas de Oro Nacional, S.A. de C.V., a wholly owned subsidiary of Alamos.

HISTORY

The Mulatos project was acquired in February 2003 for $10 million. Following completion of a feasibility study, construction began in the third quarter of 2004. The mine was built at a cost of approximately $74 million with the first gold pour completed 2005 followed by commercial production on April 1, 2006. The operation was initially contemplated as a 10,000 tpd operation though with future expansion potential in mind, major components of Mulatos including the crusher/conveyor and gold recovery plant were sized for a 15,000 tpd operation. A number of expansions and productivity improvements have taken place through the years and daily crusher throughput is now capable of exceeding 20,000 tpd.

GEOLOGY AND MINERALIZATION

Geology

The Mulatos District occurs within the Sierra Madre Occidental volcanic province. Deposits in the district are hosted within a mid-Tertiary dacitic to rhyodacitic volcanic dome complex and are considered high-sulphidation, epithermal deposits. Gold mineralization is closely associated with silicic and advanced argillic alteration occurring near the upper contact of a rhyodacite porphyry and in overlying dacite flows and volcaniclastic rocks. All lithologic units of the dome complex are intensely altered. Alteration assemblages are typical of high-sulphidation deposits and show zonation patterns from distal propylitic alteration through illite to kaolinite to dickite/pyrophyllite to pervasive, vuggy silica alteration. Gold is predominantly hosted within this silicic alteration. The altered and mineralized units are locally overlain by a thick section of unaltered volcanic rocks that are believed to be post-mineral in nature. Tilting and post-mineral normal faulting associated with late Tertiary extensional (basin and range) tectonics have affected both the mineralized flow dome complex and overlying volcanic rocks. North-northwest and northeast trending faults cut all rocks in the Mulatos area. The Mulatos mine is exposed in the footwall uplift of the Mulatos extension fault.

The Mulatos deposit proper is composed of the contiguous Estrella, El Salto, Mina Vieja, and Puerto del Aire resource areas. The Escondida deposit is the faulted extension of the Mina Vieja and El Salto deposits and mineralization is believed to be continuous to the northeast to the Gap, El Victor and San Carlos mineralized areas. Although zones are often bounded by post-mineral faults, together they form a trend of 2.7km of gold mineralization starting at the north end of the Estrella pit to the San Carlos deposit.

Within the larger Salamandra Concessions, and generally within 20km from the Mulatos deposit, geologically similar high-sulfidation gold deposits, occurrences, or prospects are known. The principal ones, some of which are in the process of being evaluated and/or drill-tested, are: Cerro Pelon, La Yaqui, El Realito, El Carricito, El Halcon, Las Carboneras, El Jaspe, Puebla, Los Bajios, and La Dura.

Mineralization

Gold deposits of the Mulatos district are high-sulphidation, epithermal, disseminated gold deposits. Precious metal mineralization at Mulatos is associated with intense silicic alteration (mostly vuggy silica), advanced argillic alteration, and the presence of hydrothermal breccias. The original protoliths (dacite porphyry flow/tuff, coarse grained volcaniclastic rocks, breccias), as indicated by surface mapping and core drilling, may have contained in the order of 2-3 percent sulphide as pyrite with various amounts of enargite and tetrahedrite.

Gold mineralization occurs primarily within areas of pervasive silicic alteration of the volcanic host rocks, and to a lesser extent, within advanced argillic alteration assemblages proximal to silicic alteration. The gold-bearing advanced argillic zones are dominated by pyrophyllite or dickite alteration. Silicic rocks host approximately 80 percent of the contained gold within the deposit.

Staude (2001) describes three main mineralization assemblages. From oldest to youngest they are: 1) quartz + pyrite + pyrophyllite + gold; 2) quartz + pyrite + kaolinite + gold + enargite; 3) kaolinite + barite + gold. Free gold is commonly found in hematite-filled fractures. Gold also occurs in pyrite, as gold/silver telluride minerals, and possibly as a solid solution in some copper sulphide minerals. Supergene oxidation and perhaps remobilization and secondary enrichment of gold have been ongoing since the post-mineral volcanic cover was removed.

Gold mineralisation exists in oxide, mixed oxide/sulphide, and sulphide ore types, with pyrite as the primary sulphide mineral. The deposits are amenable to cyanidation in all ore types, but gold extraction decreases with decreasing levels of oxidation.

MINING AND PROCESSING

Mining and processing at Mulatos is via conventional open-pit mining methods followed by a four stage crushing circuit after which it is conveyed and stacked and leached on the heap leach facility. Current throughput rates exceed 20,000 tpd. Gold is ultimately recovered through a carbon-in-column circuit, and an electrowinning and refining plant.

Mining

Mining at Mulatos is by way of conventional open pit methods. The open pit mining is a typical drill, blast, load haul operation with mining in the main pit being done with 9 metre ("m") bench heights. The mine switched from a 6m to 9m bench height to improve productivity. It is anticipated that a 3m bench will be used at Yaqui and Pelon to improve selectivity.

Processing

Lower grade from the open pit is processed through four stages of crushing to a target size of 95 percent minus 3/8 inches. Run-of-mine ore is delivered to the primary crusher feed hopper by rear-dump haul trucks. Ore is first crushed to 80%, passing a 15-centimetre screen in the primary jaw crusher. Primary crushed ore is then fed to the secondary cone crusher after which it is conveyed to scalping screens where oversized ore is conveyed to the coarse ore stockpile while undersized ore is discharged and conveyed to the fine ore stockpile.

Ore is withdrawn from the coarse ore stockpile by two variable speed apron feeders and conveyed to three tertiary crushers, each with a dedicated vibrating feeder. The tertiary crushed ore is conveyed to vibrating screen where oversized ore is transferred to and crushed in the single quaternary cone crusher. The quaternary crushed ore is discharged onto the crusher conveyor and recirculated back to the vibrating screen. The undersized screened ore flows to the fine ore collection conveyor, ultimately to the fine ore stockpile. This process has "closed the crushing circuit" such that oversized material is re-circulated through the crushing process and approximately 95% of the ore passes through the 3/8-inch screen to be delivered to the pad. The higher consistency of the crushed product has positively impacted recoveries.

After crushing, lime and cement are added and the ore is conveyed to a pair of agglomerators. Once agglomerated, the ore is delivered to the leach pad for stacking and leaching via a series of portable conveyors ending with a radial stacking conveyor. The heaps are underlain by an impermeable plastic layer on top of a layer of compacted clay.

To extract the gold from the ore, a low-concentration cyanide solution is applied to the ore on the leach pad using a low-pressure irrigation sprinkler system. Alamos installs inter-lift liners on the pad on a periodic basis to reduce percolation time, which decreases the time it takes to extract and produce gold from each lift of the heap.

The resulting gold-bearing solution is channelled to the pregnant solution pond and is then pumped to the carbon-in-column circuit, where gold is recovered from the solution. The barren solution is then recirculated to the heap with added cyanide. Dore bars are produced on site and transferred to a third-party refinery for final recovery of gold and minor amounts of silver.

Source: https://www.alamosgold.com/mines-and-projects/producing-mine/mulatos-mine-mexico/default.aspx

|

Development Boomtruck Operator

- Safely move material as directed. Report and document all material moved accurately to his/her Supervisor;

- Accurately report to supervisor the material needed in storage areas U/G

Rock Breaker Operator

- Operate rock-breaker;

- Perform pre-op and post-op inspections on equipment

Scissordeck Bolter

- Install ground support as per company standard;

- Install and maintain services;

- Load development rounds

Ground Control Engineer

- QAQC of shotcrete, ground support installation, grouting, ground support auditing and paste fill;

- Document inspections of underground stoping and development;

- Rock mass characterisation and classification

Mine Engineer

- Assist with blast improvement investigations;

- Look for opportunities to improve efficiencies;

- Provide guidance to EIT’s

Construction Miner - Transmixer

- Operate equipment such as transmixer and shotcrete sprayer;

- Assist in installation, modification and repairs of UG infrastructures

Geological Technician/or Junior Geologist

- 3D digitizing of underground geological mapping and integration into 3D mining software.

- Digitize geological surface geological mapping lithology, structure and mineralization

- Digitize chip sampling of ore development headings as required

Mill Operator/Labourer

- Works and ensure all workers work in compliance with the Occupational Health & Safety Act, Regulations for Mines and Mining Plants and all other applicable government standards and regulations;

- Adheres to and enforces all safety and environmental considerations

Document Control Coordinator - Phase III

- Implement document and data management solutions with a primary focus on workflow, document control, information security and records management.

- Provide ongoing training and support to end users in the use of the document management system.

- Ensure project and operations teams comply with the document management requirements and procedures

Project Controls Manager - Phase III

- Development and implementation of project controls systems and procedures.

- Working with accounting personnel to ensure accurate reporting and approval of accruals, forecasts, and project status.

- Early identification and notification of deviations and variances to project baseline schedule and spend