Groeneveld-Beka

About Groeneveld-Beka

Groeneveld customers enjoy increased operational uptime, productivity, efficiency and safety, with reduced costs: This is what it’s all about at Groeneveld Lubrication Solutions! We accomplish this by developing and producing industry-leading automatic lubrication, oil management and safety support systems.

Active for more than 47 years

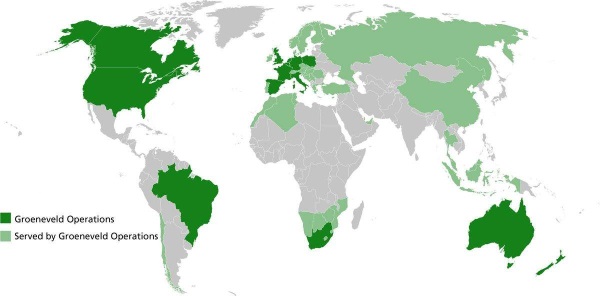

Groeneveld develops and produces innovative products and services that maintain equipment. Our lubrication solutions increase efficiency, uptime and safety in the logistics, public transport, off-road, port, agricultural and forestry sectors. Since its foundation in 1971 in Gorinchem, Groeneveld has developed into a global enterprise with approximately 700 employees. Groeneveld, part of The Timken Company, has 30 branches around the globe. In many countries, the company is also represented by independent distributors and dealers. Groeneveld is happy to assist customers with the installation and service of systems. Visit the Groeneveld website for contact details of subsidiaries, distributors and service dealers.

Your efficiency is our challenge

Our committed employees and distributors take pride in offering industry-leading products and providing best-in-class service. We enjoy developing and maintaining long term relationships with our customers. Groeneveld supports customers all over the world by helping to reduce operational costs and improving uptime and productivity of operations.

Worldwide network

With it's worldwide network of subsidiaries, dealers and distributors, Groeneveld products are installed on equipment in many different market segments. Technicians install lubrication systems that are engineered and documented by Groeneveld, with a Guideline Manual provided for each installation. We guarantee that each installation meets the highest Groeneveld standards.

Manufacturing

Groeneveld assembles all of its products in its own manufacturing facilities. Machining operations are outsourced, while components and other production materials are purchased from specialized suppliers, complying with Groeneveld’s strict quality requirements. The company continuously improves it's manufacturing and logistics by investing in people and machinery for increased productivity and quality.

Product quality and efficient processes are paramount for Groeneveld. As a first-tier OEM supplier, Groeneveld is ISO 9001 certified, while Groeneveld Manufacturing Italy is IATF 16949 certified. We help take care of the environment with our efficiency in grease use and by offering biodegradable greases. Groeneveld is also ISO 14001 certified.

Groeneveld has two plants in Italy, near Lake Como and a small operation in Israel for Greensight sensors and related software. The main plant is based in Cassago Brianza, with the second plant located in Valmadrera. Main components are assembled in Cassago, including kits and electronic components with the Engineering department and central warehouse also located here. The Valmadrera plant houses product development, sub-assembly operation and hose production, which supplies the main factory.

OEM Solutions

Both end users and manufacturers are enthusiastic about the benefits of Groeneveld systems. This is why Groeneveld products can be found on the option lists of manufacturers of buses, trailers, wheel loaders, excavators and many more. View the OEM clients page to get an overview of all manufacturers supplying Groeneveld systems ex-factory.

The Twin automatic lubrication system can be found on the option lists of many leading manufacturers.

Cassago Brianza plant

In the Cassago plant, all main components are manufactured. Also, kits of distribution blocks, metering units, tubes and electronics are assembled.

Cassago Brianza plant

Valmadrera plant

The Valmadrera plant specialises in sub-assembly work and in cutting and filling hoses.

Valmadrera plant

World Class Manufacturing

Groeneveld focusses on continuous improvement of all logistics, production and organizational processes. As a World Class Manufacturer, Groeneveld applies SixSigma principles with lean manufacturing and development processes.