The Freymond Group of Companies

Who We Are

Exerts from an article in Forestry Life, Canada's Quarterly Forestry Magazine (Spring 2002 Issue)

Over 50 Years of careful growth....Freymond Lumber

Once you understand the background of the people who populate the Ottawa valley region, you understand what makes them who they are.

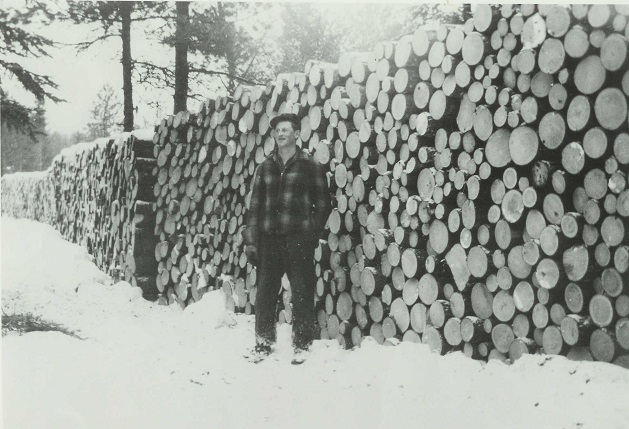

Men like Peter Freymond, an immigrant from Switzerland who grew up during the Great Depression and survived the Second World War, are a very conservative lot who make decisions based on sound judgment. His work ethic was forged from hard times and toiling on the rocky soil of North Hastings.

Peter was only twenty-one years old when he began logging on his farmland because the soil wasn't yielding very well. Armed with a crosscut saw and a team of horses was how Peter Freymond began what is today a successful family run operation.

Freymond's sound business sense and hard work eventually resulted in the purchase of the C.W. Bierworth & Sons' sawmill, the oldest operation in the area.

With Peter at the helm growth has been approached with caution and patience. Any expansion has always been sought after careful analysis. The company's first major expansion occurred in 1982 when they built the present day mill in Bancroft, Ontario.

Production demands during the 1980's resulted in an expansion in 1990. This expansion allowed the utilization of smaller logs from 4" to 35" in diameter and from 8' to 18'. A 200% increase in output was achieved.

Peter's work ethic and conservative nature has been passed on to his sons, Lou and Dan, who now run Freymond Lumber. Lou takes care of the timber supply and Dan oversees the milling operation with some overlapping.

Sixty percent of the lumber processed at Freymonds comes from private woodlots and forty percent from crown land.

Lou Freymond states that the company utilized a shelterwood form of harvesting and selective cutting. He further adds that in the last few years, private woodlot owners have become more aware of sustainable forest management.

At present, the mill processes eight million board feet a year, 70% hardwood and 30% softwood lumber. Most of the hardwood is #2 common maple that is turned into flooring and sold mainly in Ontario and Quebec. What does the future hold for Freymond Lumber?

Decisions are not taken lightly by the Freymonds. Like their father any change in the operation is weighed and the cost counted by Lou and Dan.

Two areas of their operation that are being scrutinized is the implementation of mechanical harvesting and the loss of wood fiber in the debarking process.