Borets Canada

Electric Submersible Pumps

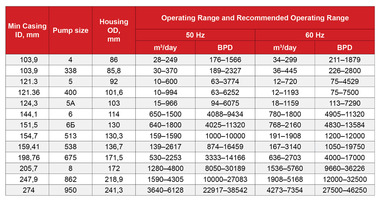

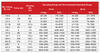

Borets manufactures a full-range of electric submersible pumps designed with flow rates of 10 to 6128 m3/day and head of 100 to 3500 m.

The recommended operating range of all pump configurations is determined. It is essential to operate the pump within this recommended range to achieve optimum efficiency and increase time between failures.

Our company offers several pump configurations depending on pump construction and pump stage design to deliver reliable and efficient performance in real downhole conditions and meet the most demanding requirements of our clients.

Borets ESP can be deployed in any operating environments, including more demanding downhole conditions such as high solids content, GOR and increased temperatures of process fluids.

In order to improve operation reliability in harsh abrasive conditions Borets offers different pump configurations, namely compression, abrasion-resistant compression and packet assembly pumps.

The Borets pumps use the following stages of different configurations: ESPD, ESPMIK and ESPDP.

• ESPD dual-pad stages.

• ESPMIK single-pad stages that have an unloaded impeller with extended hub.

• ESPDP dual-pad stages manufactured using powder metallurgy methods.

ESPDP stage pumps ensure high resistance to corrosion, friction pairs wear and hydro-abrasive wear. Furthermore, pumps with powder metal stages are more energy efficient due to finely finished surfaces of impeller flow channels.

Pump head and base are made of high-strength steel. The heads and bases of pumps operated in aggressive well conditions are made of corrosion-resistant steel.

To avoid radial wear and vibration when operated in harsh environments, pumps are fitted with radial tungsten carbide bearings.

Borets offers corrosion and wear-resistant metal coatings applied to ESP housings, heads and bases that effectively address aggressive well conditions. Increased hardness and ductility prevent these coatings from flex cracking when installing and pulling out the downhole equipment.

Borets Company has developed anti-scaling polymer coating that allows for reduced scaling and low corrosion of ESP components that are used in high-temperature aggressive environments. This coating is applied to pump stages, tubes, fasteners, heads and bases. Anti-scaling polymer coating protects ESP stages from scaling and improves corrosion, wear and chemical resistance.

Featured Products