Beka-Lube Products Inc

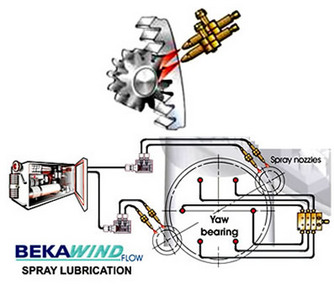

BEKA Wind FLOW

Spray Lubrication System

• For special lubricants with high solids contents

• Very efficient, non-contacting technology

• Lubrication even during intermeshing

• Clean alternative to conventional gear lubrication

Application: Pitch drive, yaw drive

More information

Application

The problem

Lubricant apply with lubricating pinion

• Overlubrication

• Lubricant drains off without use

• No sufficient lubrication in case of low relative motions

The BEKAwind solution

The innovative spray lubrication system:

• Tried-and-tested technology

• Precise and saving lubricant appy

• Lubricant is sprayed between the tooth faces – even during intermeshing

Spray lubrication:

Lubricant apply even during intermeshing

The Advantages of BEKAwind FLOW:

• Precise apply of the lubricant

• Lubricant supply between the gear wheels even during intermeshing and standstill

• Only the friction points are lubricated

• No need for blade or yaw movements for lubricating

• Very low lubricant consumption

• No over-lubrication and therefore no pollution

• Exact monitoring of the lubricant use

BEKAwind FLOW can be used for the lubrication of all open toothings and friction points of wind converters.

The Advantages of BEKAwind at One Glance:

• Reliable and monitored lubrication of the wind converter

• Lower maintenance costs by automatic lubrication

during operation

• Reduced lubricant consumption by precise lubrication

• No more environmental burden and pollution by

innovative spray lubrication systems

• Monitoring module for maintenance system and wind converter as add-on tool or stand-alone solution with world-wide access

• Retrofitting kits for wind converters

BEKAwind FLOW Spray Lubrication System

The spray lubrication system BEKAwind FLOW was developped especially for the operation in wind converters.

The BEKAwind FLOW spray lubrication system divides very small lubricant quantities with the help of compressed air, distributes the oil/air mixture with special mixing distributors and sprays it directly onto the friction point. With this procedure it is possible to apply the lubricant even during the intermeshing and standstill of gear rims. This leads to a considerable reduction of wear and tear by micro movements, stick slip and tribo corrosion. By the use of smallest possible lubricant quantities, each kind of pollution of the surrounding of the lub point is avoided. There is no need for any wipers or disposing devices.

The drawing shows a BEKAwind FLOW spray lubrication system for the lubrication of yaw drive and pitch drive.

The system consists of a compressor unit (compressor, pressure vessel, controller), pneumatic pump, 2/2 way solenoid valve, mixing distributor and spray nozzles.

The compressed air produced by the compressor is stored in a pressure vessel. If required, the pneumatic pump is actuated by the compressed air. The pump generates the spray mixture, which is distributed evenly by the mixing distributors to the connected spray nozzles.

For the lubrication of the pitch gear a rotating duct is necessary. If it is not available and cannot be retrofitted, it is possible to install a rotating compressor unit.

Technical Data

Lubricant: grease up to NLGI 00

Number of spray nozzles: up to 8

Temperature range: -20 to +60°C

Compressor Station

The compressor generates compressed air and keeps it in the pressure vessel at the necessary pressure. If the system is activated, e.g. if the motors of the yaw drive start working, compressed air is applied to the pneumatic pump. The pump now produces the oil/air mixture.

The mixture is divided evenly to the different spray nozzles by the mixing distributors. The spray nozzles care for the precise wetting of the friction points.

The lubrication system can be controlled and monitored either by an integrated controller or by the control system of the wind converter.

Technical Data

Voltage: 230 V AC

Output at 5 bar: 38 l/min

Working / sec.pressure: max. 7,5/5,0 bar

Capacity pressure vessel: 25 l

Adjustment safety valve: 10 bar

Pneumatic Pump

The pneumatic pump is triggered and actuated by a 3/2 way solenoid valve Y1 with release.

The pneumatic piston is pressed by a spring into the upper position and sucks the lubricant into the ring chamber. Caused by the special design, the pump can deliver lubricants with high solids contents.

The compressed air presses the piston down and the lubricant in the ring chamber is delivered to the outlet.

Technical Data

• Reservoir capacity: 4 kg

• Compressed air supply: 4 to10 bar

• Lubricant: grease up to NLGI 00

• Delivery rate: 0,1 - 1 cm3/stroke

• Operating temperature: -25 to +70°C

• Level switch: change-over contact

• Switching current: 1 to 60 A

Mixing distributor

The lubricant is transported with compressed air along the interior tube walls.

The patented splitting insert of the FluiLube mixing distributor divides the lubricant. A porous insert collects the liquid particles, splits them up to tiny droplets

(0,15 mm or less) and distributes them like a drizzle to the airstream.

This principle guarantees a homogeneous mixing ratio even with several spray nozzles.

Spray Nozzles

The spray nozzles precisely apply the lubricant onto the gear rim without polluting other components.

Size and spray form of the spray nozzles depend on the application.

Featured Products