Hepburn Engineering Inc.

Mine Hoist

Hepburn Engineering Inc. designs and supplies state-of-the-art mine hoists and electrical controls for the full range of operating requirements, from shaft sinking and development up to the largest production capacities, as well as complete rebuilding or upgrading services for existing hoists of all types.

Hepburn Hoist Manager is a powerful state-of-the-art window to the hoist for monitoring and control. Designed to improve hoist automation, safety, maintenance and operating efficiency, this comprehensive and user friendly system can be retrofitted to existing hoisting plants as well as incorporated into new hoists.

Continuing a tradition of innovation, Hepburn has introduced the cutting-edge Hoist Reporter as a companion to the Hoist Manager. Using the Hoist Reporter, mine management personnel can get real time hoist status and production reports at their own desks, using standard web technology.

To ensure that your Hepburn Hoist operates at peak performance, Hepburn has now introduced Hoist Care, a secure remote access solution specially designed for online mine hoist support by Hepburn Hoisting specialists.

Hepburn Engineering designs, specifies and supplies the mechanical, hydraulic, electrical and control components for each hoisting system, new or rebuilt, to produce an efficient, integrated package best meeting the customers requirements. A variety of configurations, drive and braking arrangements are available and each hoist is tailored to the specific application.

HEI Mining group also supplies automated ore pocket weighing systems, head and deflector sheaves, retrofit electrical controls for existing hoisting plants, hoist inspections and field service, technical studies and a range of other hoist related equipment and services.

The efficiency of an underground mine and the safety of mine personnel are dependent upon the operation of the hoist. This demands materials, design and construction to very high standards.

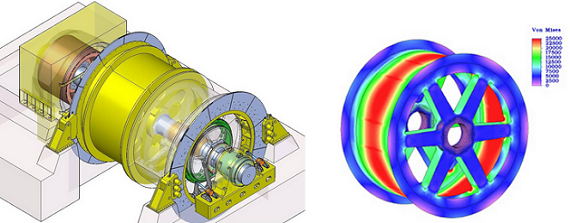

Working with the latest CAD software and Finite Element Analysis techniques, Hepburn engineers use their skills and knowledge to produce efficient, reliable equipment with a solid basis in well proven designs.

This experience and expertise is also invaluable in assisting our customers in the evaluation of the best solutions for their hoisting requirements, whether it be for specifying a new hoist or the refurbishment or upgrading of an existing hoist.

HEI’s Mining group supplies hoists and controls for all types of applications including single drum, double drum, friction ( Koepe ) service or skip hoists, for single or multi-level hoisting. They are among the most technically advanced hoists available to the industry with full digital controls and automation.

Hepburn’s worldwide installed hoist population is extensive and a strong international presence is maintained by a network of effective local representatives and a corporate commitment to excellent service and reliability.

Over the years Hepburn has acquired and absorbed the engineering designs, data and detail drawings for the mine hoist technology of Canadian Ingersoll Rand, Fullerton, Hodgart & Barclay, Westinghouse Canada and Ottumwa. This places Hepburn in a unique position to provide OEM spare parts and service, overhauls or refurbishing for the many hoists previously built by these manufacturers.