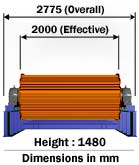

D7 Apron Plate feeder

The MMD D7 Apron Plate feeder is the most popular feeder we manufacture, mainly because of its high capacity and strength. Mostly used in surface applications it is suitable where large feed sizes are required or where the throughput rate is not suitable for a D4 feeder.

Standard Features

|

This facility, incorporated into all the MMD Feeders allows loading of material directly onto the feeder plates even whilst operational. |

|

The torque transmitted by the sprockets provides adequate drive to start the feeder with a full load of material. |

|

The apron plates, made from rolled sections provide an impact resistant surface for material to be loaded on to. |

|

Heavy Duty sealed and lubricated chains and rollers ensure smooth travel of the deck during operation. |

|

The head and tail shafts are manufactured from high strength steel to transmit the high torque loads required to pull out from a fully laden start up. |

|

With a strong lightweight open construction the mainframe provides easy inspection and minimises supporting steelwork for easy site installation and maintenance. |

|

A variable speed hydraulic / electro-mechanical drive is fitted to provide a simple method of controlling throughput. |

Optional Features

|

In-Built Fines Retrieval System Fine material from underneath the feeder is brought back to the top of the feeder to be deposited with the rest of the material. |